Low temperature (heat pump) belt dryer

Category

Enquiry

Parameter download

Principle

◆ The low-temperature drying unit is a professional equipment that utilizes the Carnot cycle principle and is equipped with a combination of air supply system, heat exchange system, etc. It is a new type of high-efficiency and energy-saving drying unit. According to the Carnot cycle principle, a small amount of electrical energy is consumed to drive the compressor to compress the medium into high-temperature and high-pressure gas, which enters the condenser to release heat. The heat released by the condenser is sent to the drying chamber by the circulating fan, which heats up the materials in the drying chamber and repeatedly circulates to absorb moisture from the materials. The moisture is continuously vaporized and removed from the surface of the materials, and then cooled and dehumidified by the evaporator to discharge the moisture in the materials, achieving material drying.

Characteristic

◆ Adopting closed-loop or micro negative pressure operation, there is no odor overflow or a small amount of overflow treatment, with low energy consumption and low emissions.

◆ Adopting low-temperature drying (generally ≤ 80 ℃) to avoid natural or easily caused high-temperature drying corrosion, with high safety.

◆ Adopting a low-temperature drying form can greatly reduce the energy demand during the drying process, thereby greatly reducing operating costs (heat pump heating requires a large investment and high operating costs).

◆ Mainly suitable for the treatment of bulk sludge with a feed moisture content of 50-75% and low corrosive components in the sludge.

◆ Large processing capacity, can adopt single-layer or multi-layer structure design, can directly dry sludge with a moisture content of ≤ 75% to about 10%.

◆ High degree of automation, simple process structure, energy-saving and environmentally friendly, widely applicable.

◆ The low-temperature drying process is based on a temperate drying machine, using hot water, electricity, or low-temperature waste heat as a heat source. The drying temperature is generally between 50-80 ℃ for drying operation. The evaporated warm air is condensed by a condenser (or heat pump) to circulate and achieve low-temperature drying.

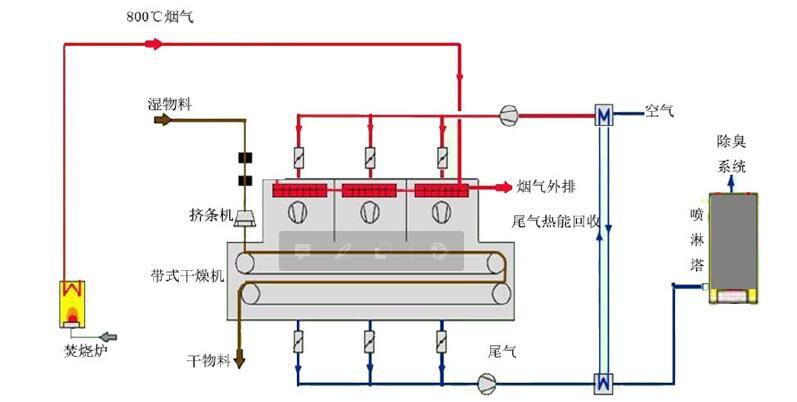

◆ Low temperature belt dryers generally adopt two types: closed-loop circulation structure and micro negative pressure structure, among which the former can adopt heat pump condensation cycle form and direct condensation cycle form.

Belt drying process

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.