Spin Flash Dryer

Key words

Category

Enquiry

Parameter download

Principle

◆The blower blows the heated air at the appropriate speed from the bottom of the dryer into the drying chamber along the tangent trajectory for mixing and crushing. The material enters the main body of the machine from the Quantitative feeder. The heated air has the efects of shearing, blowing, and rotating on the material, and it breaks the material into ltte particles due to centrifugation, shearing, olliding, and friction. The water contained in the material can evaporate Quickly in this case. In the lower part of the dryer, the mixing blades can disperse and break clusters of large and wet particles. The particles with low moisture content and small particle size are raised by the rotary airflow, and are further dried during the ascent. In the dual- phase rotating flow of gas and solid, the solid phase has greater inertia than the gas phase, the relative velocity between the two phases is large, and the mass transfer and heat conduction between the two phases are enhanced. The dried material is collected by a cyclone dust collector or a bag-type dustcollector. The exhaust gas is discharged through the induced draft fan (or discharged after washing. cooling and condensing).

Features

◆This model is applicable for the continuous mass drying of powdery and granular materials with high moisture content and materials that shape like filter cakes.

◆A variety of feding devices are avilable; the feeding is continuous and stable; it is unlikely to have the bridge formation during the feeding process.

◆The low part of the dryer can be equipped with a cooling device as needed to avoid the bonding and carbonization of the material at the bottom where the temperature is high.

◆The special hermetic seal and the unique bearing cooling device can effectively extend the service life of the transmission part.

◆The secondary heating and drying method can be added to the machine based on the design requirements to effectively extend the retention time of drying and reduce the moisture content in the dried material.

◆The drying chamber can be equipped with a grading ring and a spinning disk, so that the fineness of the material and its final moisture content be adjusted appropriately.

◆The circumferential air velocity in the drying chamber is high, and the air flow spirals upwards along the wall of the main machine. In this case, not only the height of the main machine can be reduced, but the retention time for drying can also be extended. The wall can also be swept at the same time.

◆The two spin flash dryers of Model 20 our company manufactured in 2008 were scessully applied by Hubei Sanonda Co.,Ltd; our company designed and produced the spin fAash dryers specifially for processing graphene in 2016. and they were also sucessfully applied.

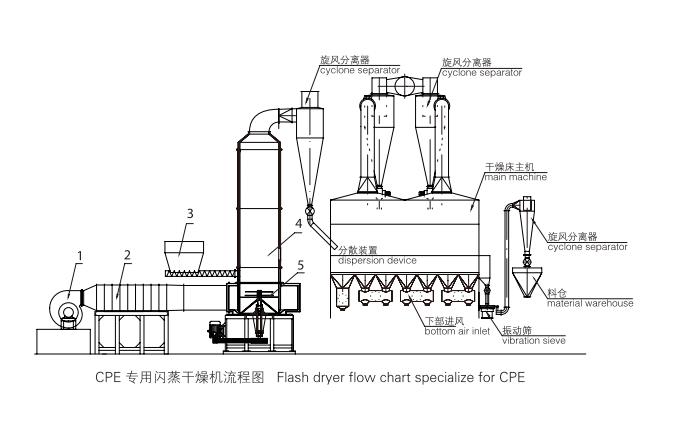

Flow Chart

Stucture Diagram

Technical Specifications

| Model | Barrel Diameter (mm) | Main Machine Size (mm) | Power of Main Machine (kW) | Amount of Air Flow (m³/h) | Evaporated Moisture(kg/h) |

| XSZ-4 | 400 | 500×3500 | 4 | 1250-2500 | 25-70 |

| XSZ-5 | 500 | 600×4000 | 5.5 | 1500-4000 | 30-100 |

| XSZ-6 | 600 | 700×4200 | 7.5 | 2500-5000 | 40-200 |

| XSZ-8 | 800 | 900×4600 | I | 3000-8000 | 60-600 |

| XSZ-10 | 1000 | 1100×5000 | 15 | 5000-12500 | 100-1000 |

| XSZ-12 | 1200 | 1300×5200 | 18 | 10000-20000 | 150-1300 |

| XSZ-14 | 1400 | 1500×5400 | 30 | 14000-27000 | 200-1600 |

| XSZ-16 | 1600 | 1700×6000 | 45 | 18700-36000 | 300-2000 |

| XSZ-20 | 2000 | 2100×6500 | 55 | 22000-45000 | 400-2500 |

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.