Paddle sludge dryer

Key words

Category

Enquiry

Parameter download

Principle

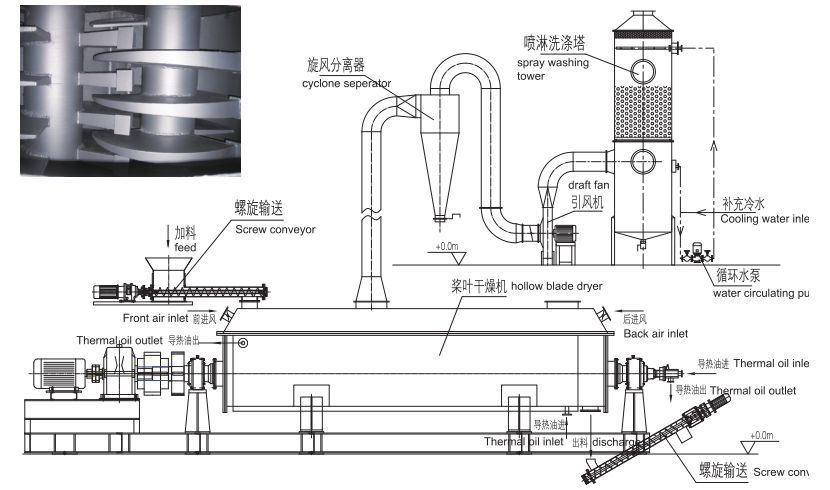

◆ Jinling Company is a professional manufacturer of blade drying machines. The wedge-shaped blade drying machine is the first generation of traditional products in China and is a low-speed stirring drying machine with conduction heating. A jacket is installed on the dryer cylinder, and a hollow blade is installed on the hollow shaft. A heat carrier is introduced into it, and the wet material is fully heat and mass transferred with the hot surface of the cylinder and blade under the stirring of the stirring blade, in order to achieve the purpose of drying. The structural form is generally horizontal, double axis or four axis.

◆ The company has made a series of improvements and optimizations specifically for transmission, thermal expansion, blade structure, welding process, sealing, etc., greatly improving performance and service life.

Drying process of propeller blades

| Configuration | Dual axisDouble shaft | Four axesFour shaft | |||||||||

| Model | 5type | 15type | 20type | 40type | 60type | 90type | 100type | 120type | 150type | 200type | 300type |

| Heat transfer aream² | 5 | 15 | 20 | 40 | 60 | 90 | 100 | 120 | 150 | 200 | 300 |

| Host powerkw | 4 | 15 | 18.5 | 30 | 45 | 55 | 75 | 90 | 110 | 132 | 220 |

| Remarks | Using different materials and configurations according to different characteristics and requirements | ||||||||||

Characteristic

(1) The heat required for drying is mainly provided by the hollow blade wall arranged on the hollow shaft, while the heat transfer from the jacket wall only accounts for a small part, so the heat transfer area per unit volume of equipment is large and the footprint is small.

(2) The machine adopts conduction heating method for heating, and all heat transfer surfaces are covered by materials, reducing heat loss; The heat utilization rate can reach over 85%.

(3) The blade adopts a large and small head inclined surface structure, which has a certain squeezing and dispersing ability and can improve the heat transfer effect of the blade. The inclined surface of the rotating blade generates a dispersing force due to the combined motion of the filter cake or powder particles, making it easy for the material attached to the heating surface to detach; In addition, due to the reverse rotation of the two axis blades, they alternate in segmented compression and expansion, which has the function of stirring and shearing, thereby improving the drying efficiency.

(4) It can achieve continuous and fully enclosed operations, reducing manual and dust emissions.

(5) The exhaust gas treatment system generally adopts negative pressure form and is equipped with cyclone separator, bag or water film dust collector to reduce exhaust air volume and dust.

(6) Due to the large and small head splicing structure and upper and lower layer distribution design of the propeller blades; The angle of the scraper is small, and the pushing force is insufficient; The welding force of blades is prone to corrosion, leakage and other problems; Moreover, the overall design of the equipment needs to be tilted, resulting in uneven force distribution, high resistance, and high maintenance rate, making it difficult to expand the equipment. The single unit area of a dual axis blade dryer is generally designed to be less than 150 square meters.

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.