Vacuum disc sludge dryer

Key words

Category

Enquiry

Parameter download

Descriptions

◆ Jinling Company is a professional manufacturer of vacuum disc sludge dryers; National Invention Technology (No. ZL 2013 2 0370333) 4) The first set of products in the country.

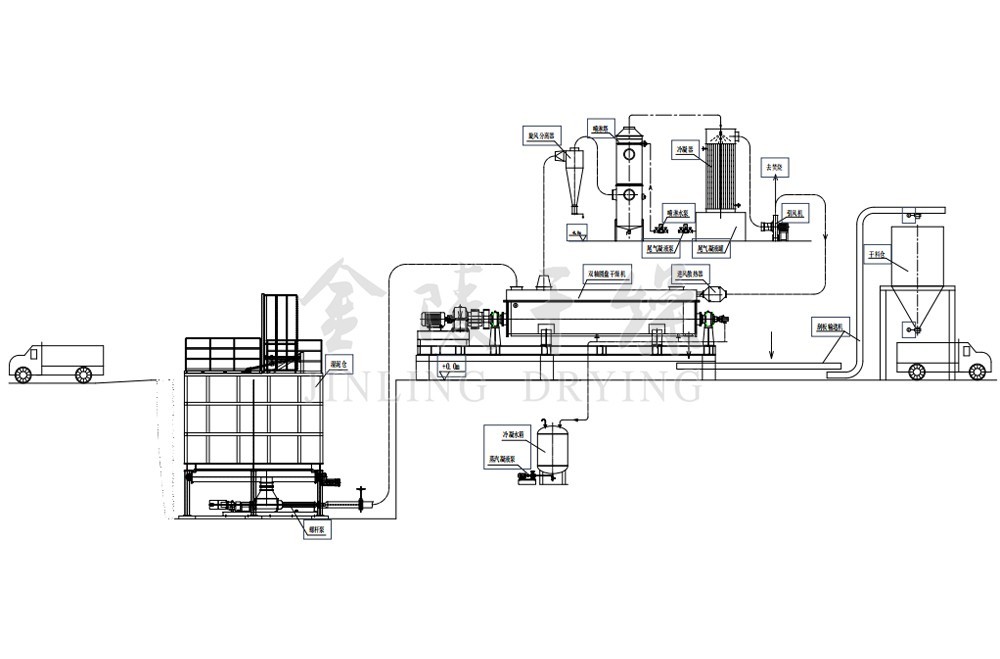

◆ Our company specializes in developing and designing a low-temperature closed and continuous drying process equipment for highly toxic and solvent containing flammable and explosive sludge. This not only adopts closed operation and condensation recovery, but also greatly improves safety; Moreover, while improving drying efficiency, it greatly reduces exhaust emissions, thus truly achieving the goals of safety, energy conservation, and environmental protection.

◆ Mainly used in chemical raw materials, pesticides, chemical sludge, etc. Specially designed for the drying treatment of oily sludge and coal chemical sludge, it is currently a substitute for imported equipment and one of the systems with high safety and stability in the sludge drying process.

◆ The oil containing sludge disc dryer innovatively designed and produced by the company in 2013 has been successfully applied.

Features

◆ The company has independently innovated and designed various structural forms of vacuum disc drying processes, which have been widely put into production and application. The stability, efficiency, strength, continuity, and other aspects have been greatly improved;

◆ The equipment has a compact structure and occupies a small area. A single unit can be designed to produce large double axis or single axis disc dryers with an area of ≤ 500m2;

◆ High heat utilization rate, using conduction heating method, all heat transfer surfaces are covered by materials, reducing heat loss, and the heat utilization rate can reach over 85%;

◆ It has self-cleaning ability and can improve the heat transfer effect of the disc. The dispersing force generated by the combined motion of the inclined surface of the rotating disc and the particle or powder layer makes the sludge attached to the heating disc easy to fall off, and due to the reverse rotation of the dual axis blade, the alternating segmented compression and expansion of the stirring shear function, the heat transfer is uniform and the heat transfer efficiency is improved;

◆ It can achieve continuous, automated, and fully enclosed operations, reducing exhaust and dust emissions;

◆ Low exhaust emissions, thereby reducing the cost of exhaust treatment. Multiple exhaust treatment devices can be selected to meet emission standards;

The disc is an integral molded structure with few welds, smooth surface, low adhesion, low resistance, and low installation power;

Adopting high negative pressure or vacuum design to reduce boiling point and achieve the purpose of closed low-temperature drying operation;

◆ Overall reinforced design ensures better strength and service life;

The unique processing and assembly technology of Jinling Company ensures the concentricity of the equipment and superior sealing performance at both ends;

◆ Half tube jacket heating and integral jacket heating types can be designed according to different situations;;

Different discharge forms can be designed according to material requirements to ensure the drying retention time of materials and further improve overall efficiency.

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.