Mid temperate sludge dryer

Key words

Category

Enquiry

Parameter download

Performance characteristics

1) Efficient and energy-saving, capable of utilizing waste heat circulation for heating.

2) Continuous mass production, simple operation, and low operating costs.

3) Can achieve automated operation, safe and reliable.

4) The thickness of the material layer, conveying speed, and operating temperature can all be adjusted, with a wide range of applications.

5) Low operating cost, high thermal efficiency, especially suitable for drying sludge with final moisture content<20%.

6) The number and structural form of drying modules can be adjusted according to different processing capacities and sludge moisture.

7) Mainly suitable for waste gas recycling or drying treatment of highly corrosive chemical sludge.

Process principle

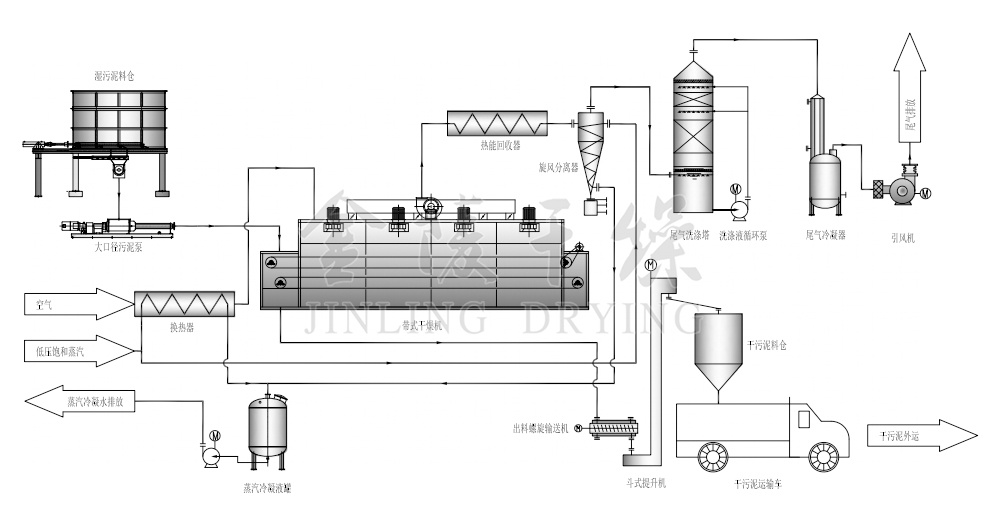

◆ The main body of the belt type sludge drying system consists of multiple unit structures. Dehydrated sludge is sent to the extruder through the feeding system and evenly laid on the drying belt, which sends the sludge into the main structure of the device; In the drying chamber, heating gas raises the temperature of the drying chamber to the set value, and hot air enters the drying device from the upper or lower part of the device, flowing through the entire drying zone. When air flows through the sludge laid on the drying belt, it takes away the moisture in the sludge, achieving the drying of the sludge.

◆ The exhaust gas can be designed to undergo heat recovery or condensation cooling, and the exhaust gas is treated to absorb and oxidize most of the organic substances. In addition, some alkaline molecules (such as amines) are also removed at this stage. The system mainly consists of the following parts: a combined exhaust gas washing unit (acid washing/alkali washing/oxidation washing, automatic preparation and batching unit (acid/H2SO4)).

◆ The system mainly consists of pre-treatment granulation system, heat exchange system, drying system, heat recovery system, exhaust gas treatment system, and automatic control system. Using steam, waste hot water, and boiler flue gas as heating sources for hot air, the hot air is heated to a certain temperature and enters the belt dryer to dry the well shaped (strip-shaped) sludge through convective heat exchange. The majority of the heat energy from the exhaust gas is recovered, and the recovered heat energy is used as a preheating heat source for the intake.

Technical Specifications(Reference)

| Number | 30t/d | 50t/d | 75t/d | 100t/d |

| Feed moisture content% | 80 | |||

| Discharge moisture content% | 30 | |||

| Material outlet temperature ℃ | 80 | |||

| Cycle temperature ℃ | 130 | |||

| Exhaust gas temperature ℃ | 80 | |||

| Hourly evaporation rate kg/h | 8875 | 1479 | 2218 | 2958 |

| Installed power kw/h | 120 | 140 | 170 | 200 |

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.