Complete set of hazardous waste incineration treatment technology and equipment

Category

Enquiry

Parameter download

Descriptions

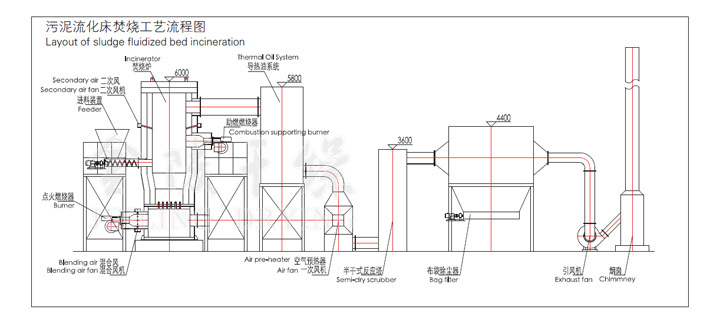

The incineration process currently mainly adopts rotary kiln incineration technology and fluidized bed incineration technology in China. Widely used for incinerating various types of solid, semi-solid or liquid waste, especially suitable for industrial waste and hazardous waste with high moisture content and difficult treatment.

Principle

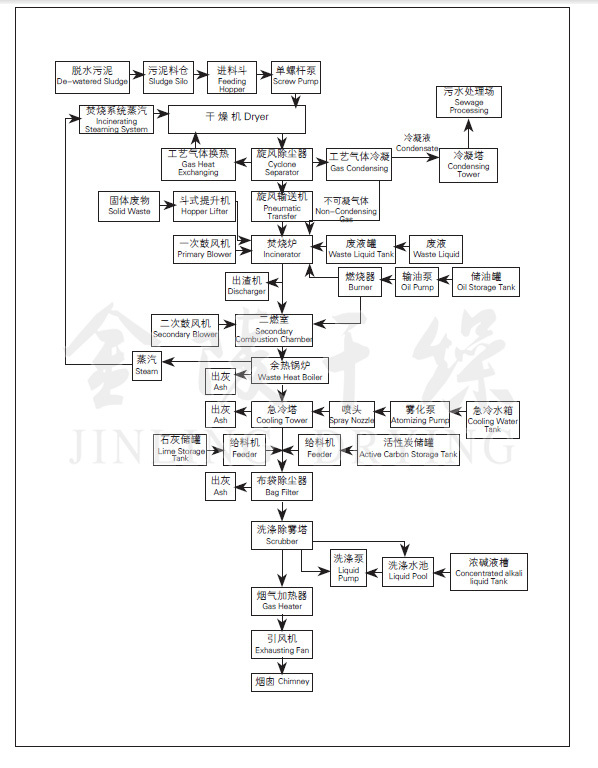

The materials undergo drying, combustion, and pyrolysis processes in the rotary kiln. The kiln tail is located at the lower part of the secondary combustion chamber and has an independent self-supporting mechanism, which is connected to the secondary combustion chamber and the scraper slag extractor. The burnt slag is discharged by the scraper after water quenching, and it is also conducive to guiding the rotary kiln flue gas to the secondary combustion chamber. The flue gas generated by the incineration of hazardous waste in the brick kiln enters the secondary combustion chamber for further combustion, and the combustion temperature in the secondary combustion chamber reaches 1100 ℃ -1300 ℃. To fully recover and utilize the thermal energy of flue gas, the high-temperature flue gas after incineration is recovered by a thermal energy recovery device. To avoid the low-temperature re synthesis of dioxins in the flue gas, the extremely cold tower rapidly cools the flue gas within 1 second, reducing it from 500 ℃ to below 200 ℃ and avoiding the synthesis area of dioxins. Then, it undergoes dry acid removal, bag dust removal, wet acid removal, activated carbon adsorption, flue gas heating, and enters the chimney. After passing through the flue gas online monitoring system, it meets the emission standards.

Main features

1. Wide applicability, stable and reliable operation.

2. Simple operation and maintenance, long service life.

3. High degree of automation, adopting an intelligent central monitoring system. Compatible with real-time transmission and processing of data networks.

4. Waste heat utilization can be carried out.

5. The incineration efficiency is high, and the removal and decomposition rate of harmful components can reach over 99.99%, which can meet the requirements of complete harmlessness.

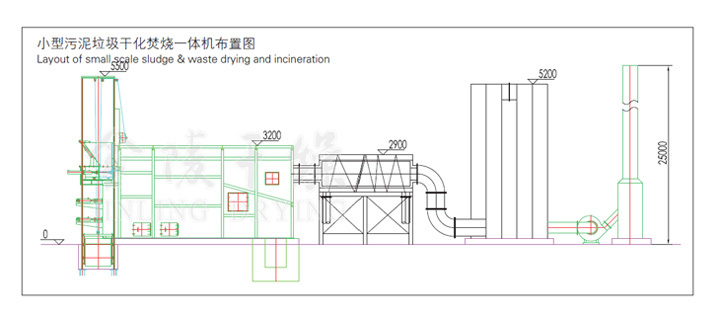

Process flowchart of sludge "drying incineration" treatment (reference)

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.