Integrated Gasification and Disposal System for Household Waste

Category

Enquiry

Parameter download

Descriptions

▲ Currently, the main treatment methods for household waste, leachate, and sludge are landfill, incineration, and gasification processes. The landfill method poses hidden dangers such as occupying a large amount of land and polluting groundwater, and has been banned by many developed countries; Incineration is currently the mainstream treatment method, but in the process of domestic incineration, sulfur oxides, nitrogen oxides, and fly ash emissions are still generated, and due to the limited combustion temperature, it is difficult to avoid the production of toxic substances such as dioxins. Compared with garbage incineration, garbage gasification technology has a higher reaction temperature, avoiding the production of pollutants such as dioxins, sulfur oxides, and nitrogen oxides. It achieves high-temperature solidification treatment of heavy metals in garbage, effectively avoiding secondary pollution, and is the main development direction of future domestic waste treatment technology.

▲ However, solving the problem of urban garbage, as well as effectively treating a large amount of urban sludge and residual leachate, is also a challenge. The sludge has high moisture content and is mostly treated by co firing; Leachate contains high salt and organic components, with high treatment costs, high corrosiveness, and easy scaling and blockage. It requires large equipment investment, unstable operation, and high operating costs. Additionally, energy issues need to be addressed first. Therefore, the waste heat generated by incineration or gasification needs to be sourced, and the treatment of sludge drying and leachate both require thermal energy. Therefore, adopting a comprehensive integrated collaborative treatment process is the most effective means, especially for collaborative disposal in small towns, which is the most direct, simple, and effective disposal process to solve the problem of zero emissions in municipal environmental protection. For this purpose, the company has developed and produced a complete set of integrated disposal systems.

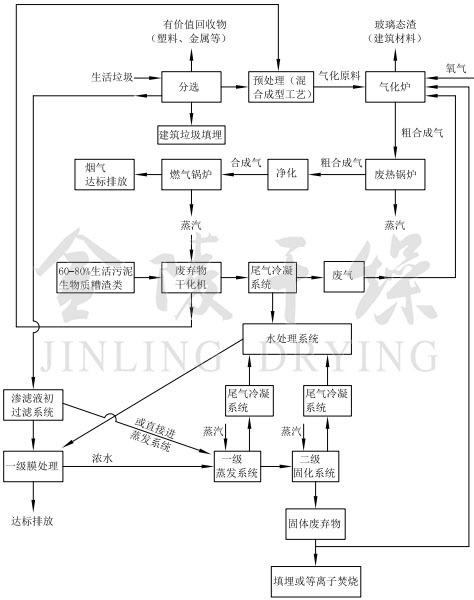

▲ Firstly, domestic waste is sorted out into high-value recyclable materials. The remaining materials, domestic sludge, and other solid waste are processed through pre-treatment processes such as dehydration and molding to become gasification raw materials.

▲ After entering the gasifier, the gasification raw materials undergo non catalytic partial oxidation reaction with oxygen at high temperature (the temperature in the reaction core area can reach 2000 ℃), producing crude synthesis gas mainly composed of CO, H2, CO2, CH4, N2, etc. The high-temperature crude synthesis gas from the gasification furnace (with a temperature of about 900-1100 ℃) first enters the waste heat boiler for heat recovery, generates steam, and then enters the purification section. Inorganic substances and heavy metals that cannot react are discharged from the gasification furnace in liquid form at high temperatures, and after quenching, they become non leaching glassy slag that can be recycled for brick making and paving.

▲ In the purification section, the crude synthesis gas is first subjected to dust removal to reduce the solid content in the synthesis gas to 1mg/Nm3, and then H2S and other components are removed. The purified synthesis gas enters the gas boiler, and the by-product steam generated is precisely used as a treatment energy for domestic sludge and leachate.

▲ The wastewater and exhaust gas generated by the system are treated comprehensively and discharged in compliance with standards.

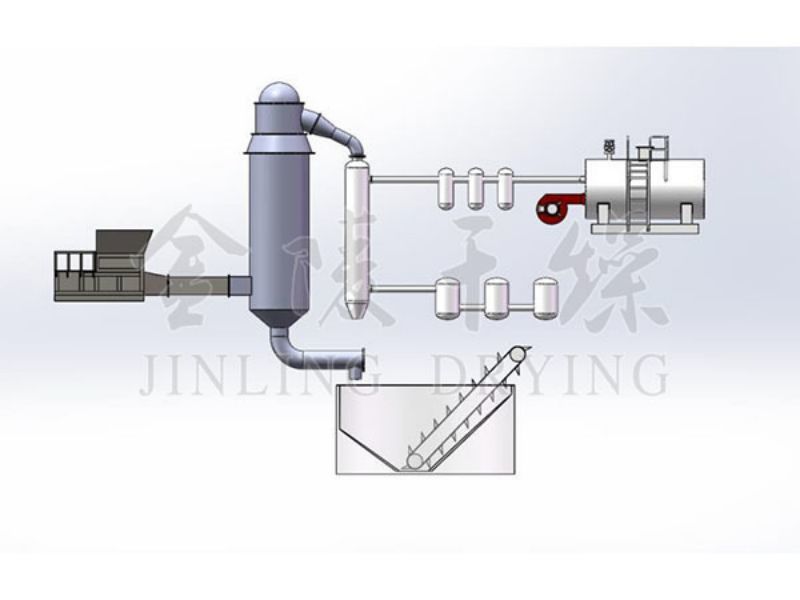

Disposal process

Technical characteristics and innovation

▲ Independent innovation adopts various means, system integration, and comprehensive processing technology to effectively solve the difficulties and pain points of system integration processing, thus truly achieving zero discharge;

▲ Especially suitable for the collaborative treatment of 30-150 tons of household waste, sludge, and leachate in small towns every day, effectively solving problems such as waste transportation, separate treatment, resource utilization, pollution discharge, etc;

▲ The system unit realizes complementary strengths and weaknesses, resource recycling, greatly reducing issues such as investment, land occupation, energy consumption, and operating costs, and improving comprehensive processing capacity and stability. The generated pyrolysis gas serves as an alternative heat source for sludge drying and leachate treatment, while the dried sludge serves as a supplementary energy source for gasification, thus achieving complementarity and achieving the goal of comprehensive zero discharge treatment.

▲ Realized the comprehensive utilization of clean, efficient, and resourceful household waste, household sludge, and leachate;

The high-temperature gasification reaction under a reducing atmosphere avoids the generation of harmful components such as sulfur oxides, nitrogen oxides, and dioxins;

▲ High temperature liquid slag discharge achieves high-temperature solidification treatment of heavy metals, avoiding secondary pollution;

▲ The synthesis gas purification process is simple and efficient, avoiding the generation of fly ash and sulfur oxides in the flue gas;

▲ The sewage discharged through circulation can be uniformly discharged after membrane treatment in the system to meet the standard;

▲ After pre-treatment and condensation treatment, the exhaust gas from drying and evaporation is directly incinerated in the system to meet emission standards;

▲ The company distinguishes between resource utilization, harmless treatment, and reduction requirements based on different government requirements and processing volumes. It can adopt different modular treatment processes and equipment, as well as separate units or comprehensive complete sets of designs for use.

Comparison of main disposal methods for household waste and sludge

| Processing technology | Technical advantages | Technical disadvantage |

| Landfill | Simple process and low investment cost | Large footprint, leachate pollution, and low level of resource utilization |

| Sludge compost | Simple process, low transportation cost, and certain resource utilization | Covering an area of, heavy metal pollution, strong odor, and poor environment |

| Burn | Large processing capacity, with certain resource utilization | The emissions of dioxins and other pollutants generated are significant, making fly ash treatment difficult |

| Gasification | The emissions of dioxins and other pollutants generated are significant, and fly ash treatment is difficult, especially for 30T-150T household waste, sludge and other treatment processes. Traditional processes have corresponding problems, and gasification technology is the most effective way to achieve coordinated comprehensive disposal of waste, leachate, biomass and sludge. Anaerobic gasification has good efficiency, high resource utilization, and low emission pollution. Europe has already formed industrialization and is currently the best disposal solution for replacing waste incineration in Chinese county towns, townships, and mountainous areas. | |

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.