Integrated treatment system for oily sludge

Category

Enquiry

Parameter download

Descriptions

▲ The treatment of oily sludge remains a challenge both domestically and internationally, and the comprehensive disposal of oily sludge is a pain point in solid waste treatment. Especially in China, the treatment of oily sludge generated from oil extraction, refining, drilling, and other processes has just begun. Currently, there is still a significant gap in the treatment and comprehensive utilization of oily sludge in China compared to foreign levels. The treatment technology is outdated, the composition of oily sludge is unstable, and most oily sludge has not been treated harmlessly, resulting in environmental pollution and resource waste. From the current situation of comprehensive utilization technology, there is a lack of high-tech and high-level deep processing and utilization technology; From a long-term perspective, recycling dirty oil and comprehensively utilizing sludge are effective ways to achieve harmlessness and resource utilization.

▲ In recent years, various methods such as incineration, biological treatment, pyrolysis, separation, extraction, and solidification have emerged to treat oily sludge. However, due to high costs, inability to recover crude oil, and secondary pollution, these methods have not been widely promoted.

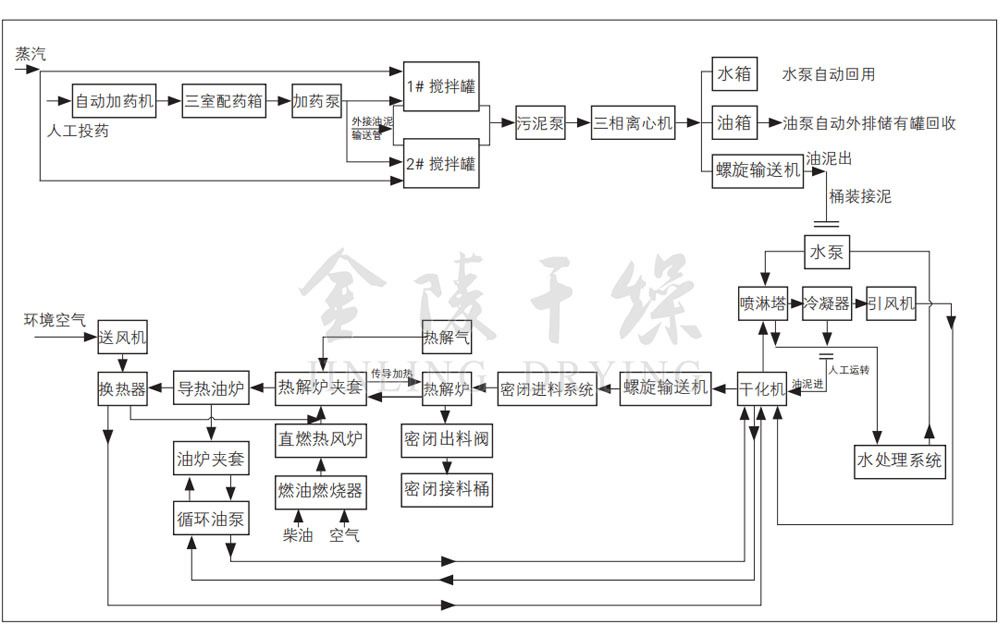

Comprehensive treatment process for oil sludge

Oil sludge conditioning and separation: By conditioning the oil sludge, the physical and chemical properties and components of the oil sludge particle surface are changed, the colloidal structure of the oil sludge is destroyed, the affinity with water is reduced, and the dehydration and oil removal performance is improved, achieving complete separation of oil, water, and slag phases. Jointly developed and successfully applied by the company.

Oil sludge drying process: It is a core device for reducing or ensuring pyrolysis stability. Due to the presence of flammable factors such as hydrogen and phenol in oily sludge, high safety requirements are required. In addition, the viscosity of oil sludge drying is high, making drying difficult and unstable. The sludge drying system independently developed by Jinling Company was successfully applied and identified as an international level in 2013.

Oil sludge pyrolysis technology: The thermal cracking process for treating oily sludge is a new harmless treatment technology for oily sludge, which requires high reaction conditions. Mainly based on high-temperature pyrolysis, the oil sludge is heated to 400-600 ℃ in an anaerobic or hypoxic state, and after pyrolysis separation, it is used as a supplementary energy source. The solid waste is then solidified and treated. Jinling Company collaborates with Sinopec and Changzhou University to innovate and develop core processes and equipment.

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.