Oil containing sludge pyrolysis treatment system

Category

Enquiry

Parameter download

Descriptions

▲ Indirect thermal cracking is the process of utilizing the thermal instability of organic matter in waste, heating it under anaerobic conditions to cause thermal desorption and thermal cracking of the organic matter. The organic matter is cracked according to its carbon to hydrogen ratio, forming a gas phase (pyrolysis gas) and a solid phase (solid residue) with high utilization value. The high-temperature pyrolysis gas is filtered or condensed (the condensate is recycled or reprocessed), and the non condensable gas solid contains a large amount of flammable components such as propane, butane, methane, carbon monoxide, etc., which can be directly reused as supplementary fuel for heating. The solid residue is used as roadbed material or landfill treatment. This pyrolysis gasifier is a core equipment independently designed and developed by our company. It can be designed with various horizontal and vertical pyrolysis devices according to the types and processing requirements of waste, providing an effective way to reduce, stabilize, harmless, and resource utilize waste.

Principle

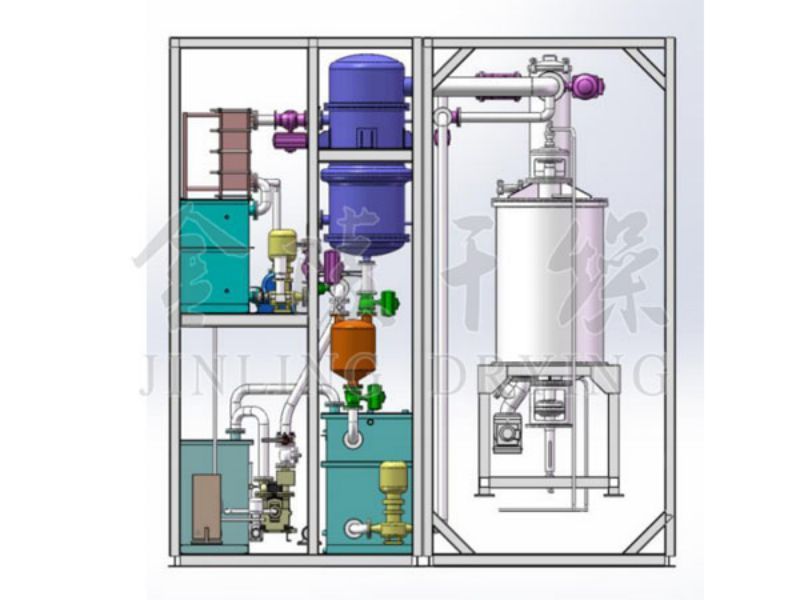

The oil sludge pyrolysis device is a process that utilizes the principle of high-temperature gasification and uses external indirect heating to heat and decompose solid waste under anaerobic or hypoxic conditions. Low temperature, medium temperature, and high temperature pyrolysis techniques can be used, with temperatures generally ranging from 300 to 800 ℃, to break the bonds of large molecules, isomerize, and polymerize small molecules in the material. The chemical decomposition process of becoming a gaseous, liquid, or solid combustible substance. The oil sludge pyrolysis system includes a feeding unit, pyrolysis unit, pyrolysis gas condensation and separation unit, water treatment unit, discharge unit, and control unit.

Technical features

▲ Low organic content in the residue after treatment;

Organic components can be recycled and reused as resources;

▲ Blockization and modular design, small footprint, and quick mobility for transfer;

▲ Adjustable heating temperature, high degree of self-control, continuous operation, convenient operation management;

Closed inlet and outlet, micro negative pressure operation, no leakage of harmful gases;

▲ Install gas locks and nitrogen protection for incoming and outgoing materials, ensuring safety and reliability;

▲ Non condensable gas assisted combustion reuse, improving resource utilization efficiency and reducing system operating costs;

▲ Specially designed internal propulsion system, equipped with a dispersing mechanism, which is not easy to block and ensures uniform heating of incoming materials, improving the thermal desorption and separation effect;

▲ Friendly human-machine interface, program control, and secure interlocking; Real time monitoring and alarm, automatic data collection, and wireless remote transmission;

▲ No chemicals are added during the processing.

| Processing technology | Solvent extraction method | Incineration technology | Hot water washing | Biological treatment | Thermal decomposition treatment |

| Technical principles | The principle of "similarity and compatibility". Realize the three aspects of oil, water, and mud phase separation |

Utilizing aerobic high-temperature combustion to achieve sludge treatment | Wash the oil sludge multiple times with a hot alkaline aqueous solution, and then achieve the separation of oil, water, and sludge in three phases through process facilities such as air flotation or cyclone | Artificially cultivated microorganisms degrade petroleum hydrocarbons and other organic matter in oil sludge into harmless substances | Deep thermal decomposition treatment of oil sludge under high temperature and anaerobic conditions |

| Technical features | The drawback is that the amount of extractant used is relatively large and the cost is high. | A large amount of pollutants are discharged, and the oil resources in the sludge are not effectively utilized | The treatment process is prone to secondary pollution and requires corresponding wastewater treatment facilities | The oil resources in the sludge are degraded and not recycled | Can inhibit the generation of toxic and harmful substances such as dioxins. Thus achieving the resource utilization and harmless treatment of oil sludge |

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.