Evaporator

Key words

Category

Enquiry

Parameter download

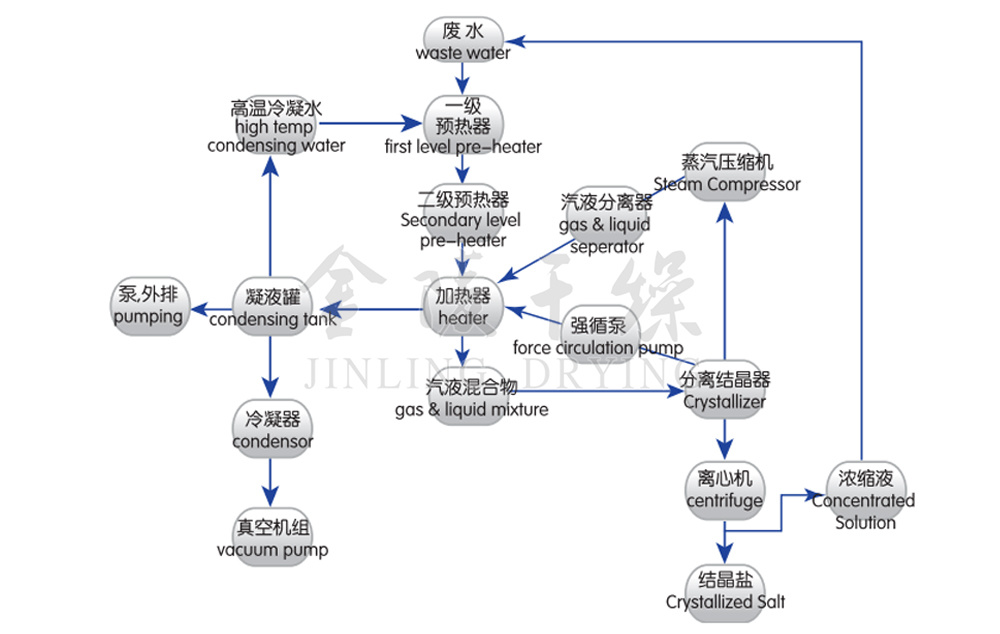

Principle

The MVR mechanical steam recompression device uses the secondary steam generated in the evaporation system to do work through a compressor, increasing steam pressure and enthalpy, circulating for heating and evaporation, fully utilizing the waste heat of the secondary steam engine condensate in the system, and achieving outstanding energy-saving effects. In addition to using fresh steam and waste heat raw material steam for driving, there is no need to use additional steam. The purpose of evaporation concentration is achieved through the self circulation of the evaporator, which can save 70-90% of energy consumption. The system consists of a preheater, evaporative heat exchanger, separator, and steam compressor.

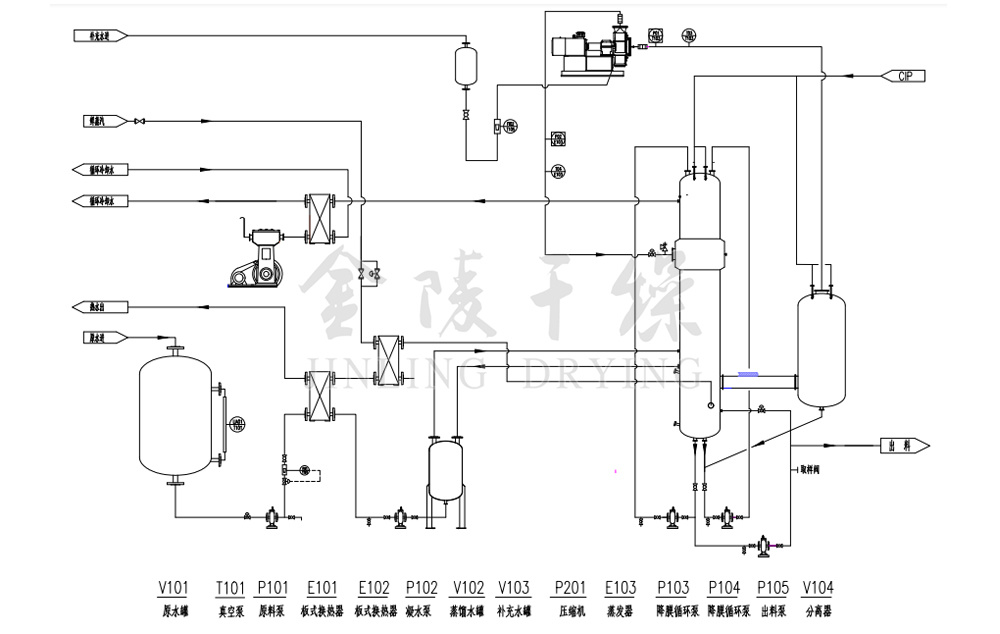

Process Chart

| Feed quantity(t/h) | 5 |

| Steam consumption(t/h) | 0.1(saturated steam) |

| Steam pressure(MPa) | 0.30(Absolute pressure) |

| Secondary steam pressure(KPa) | 50/110 |

| Secondary steam temperature (approximately)(℃) | 85/105Vapor phase |

| Liquid temperature(℃) | 92±2 |

| Heat exchanger loss(%) | ~5.0% |

| Evaporator cycle type | Forced loop |

| Total installed power(kw/h) | ~300 |

Feature

◆ For wastewater with high ammonia nitrogen and organic matter content, pre-treatment can be designed to enter the evaporator;

◆ Jinling independently designs and develops various concentrated mother liquor treatment systems to improve system stability and reduce system blockages;

◆ Easy to operate, low operating costs, and can be used in series with multi-stage evaporation;

◆ The heater, preheater, and condenser tube plates all use integral tube plates to extend the service life of the equipment;

◆ Adopting an automatic control system, automatic feeding, and automatic discharge of condensate water;

◆ Use a separation device for discharge to increase the crystal content of the discharged material. After separation, obtain most of the crystals, reduce the reflux of the mother liquor, and consume less heat energy, which is energy-saving and environmentally friendly.

◆ Adopting a forced circulation evaporator, it has the advantages of high heat transfer coefficient, high evaporation intensity, and reduced wall and pipe blockage, especially suitable for materials that produce crystals during the evaporation process.

◆ Adopting a self circulating system to keep the crystal and mother liquor circulating at all times, avoiding crystal deposition and pipe blockage.

|

Type |

Single-effect evaporator |

Multi-effect evaporator |

TVR evaporator |

MVR evaporator |

|

Energy consumption |

The energy consumption is high, and the evaporation of It water is about |

Relatively energy-saving, the four-effect evaporator evaporates It water about |

Add one effect on the basis of traditional multi-effect, but |

At Present, The Most Energy-Saving Evaporation Technology, Evaporator Evaporation It Water Large |

|

Sources of energy |

Using steam heating requires a boiler. |

A boiler is needed for steam heating. |

A boiler is needed for steam heating. |

Use electricity, no need for a boiler |

|

Operating cost |

Extremely high |

Lower |

Lower |

Low |

|

Land area |

Small |

Big |

Big |

Small |

|

Degree of white control |

Semi-white control |

Fully automatic control, uninterrupted operation |

Full white control, continuous operation |

Fully automatic control, uninterrupted operation |

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.