Forced circulation evaporator

Key words

Category

Enquiry

Parameter download

Descriptions

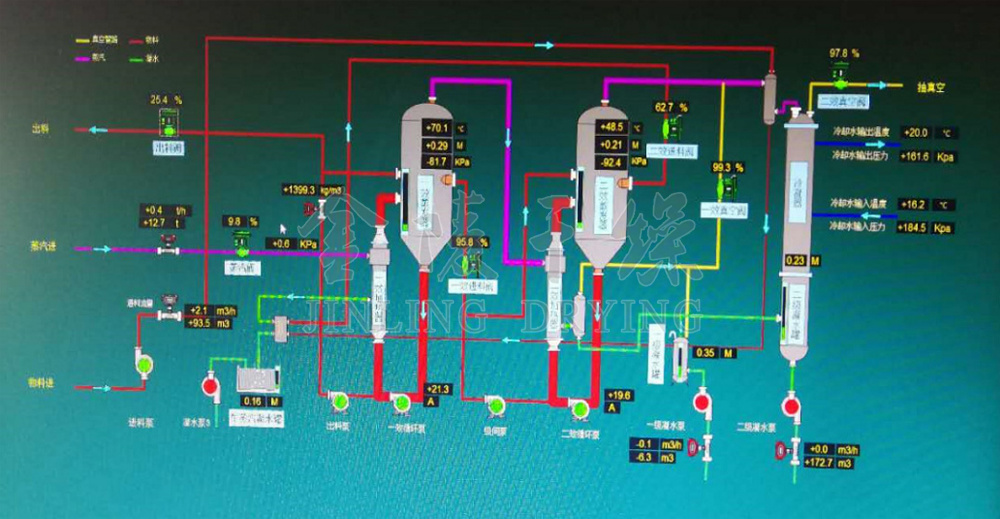

◆ The forced circulation evaporator consists of two main parts: the heating chamber and the crystallizer. After entering the separator through a forced circulation pump, the pressure of the liquid rapidly drops, causing some of the liquid to flash off. The secondary steam generated by evaporation enters the next effect evaporator for heating or enters the condenser for condensation.

◆ The system mainly consists of a heater system, an evaporator separator system, a condenser system, a forced circulation system, a conveying system, a vacuum exhaust system, an electrical control system, etc.

Application scope

◆ Mainly applicable to industries such as chemical, food, pharmaceutical, environmental protection, and waste liquid evaporation and recovery, it is a structurally, crystalline, high concentration, high viscosity, and insoluble solid evaporation and concentration method.

Typical process flow of multi effect forced circulation evaporation crystallization device

Feature

◆ The material is forced to circulate through heating, resulting in fast flow velocity, uniform heating, high heat transfer coefficient, and prevention of dry wall phenomenon inside the tube.

◆ For materials that are prone to scaling during the evaporation process, evaporation of materials with high concentration ratios and viscosities; Multiple stage evaporators can be optionally used in combination.

◆ The feed liquid is quickly heated by a heater through a forced circulation pump, and then directly enters the evaporator separator in a tangential manner from the top, resulting in good vapor-liquid separation effect.

◆ Adopting negative pressure low-temperature evaporation, suitable for evaporation and concentration of thermosensitive materials.

◆ The equipment is equipped with an automated operating system to achieve continuous operation.

◆ The device has a compact structure, small footprint, easy operation, and stable operation.

Technical Specifications

| Model specifications | Single effect | Double effect | Three effects | Four effects | |

| (kg/h) | 500-2000 | 2500-4000 | 600-15000 | 8000-50000 | |

| % | Based on the materials provided by the property owner | ||||

| % | Based on the materials provided by the property owner | ||||

| MPa) | ≥0.5 | ||||

| kg/kg | 0.67 | 0.40 | 0.30 | 0.25 | |

| T/T | 29 | 12 | 9 | 8 | |

| ℃ | 45-90 | ||||

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.