Centrifugal scraper film evaporator

Key words

Category

Enquiry

Parameter download

Feature

◆ Adopting a centrifugal sliding or fixed rotor, the accumulated material on the inner wall surface of the evaporation section of the cylinder can be quickly removed by a scraper;

◆ High heat transfer coefficient value, large evaporation capacity, simple operation, easy adjustment, automatic continuous production under closed conditions;

◆ The heating time of the material is short, between 5s and 10s, and it works under vacuum conditions, which has a better effect on the treatment of thermosensitive materials.

◆ Multiple scraper structures can be selected and combined with multi-stage evaporators to effectively adjust material concentration and evaporation processing time.

◆ The inner wall of the evaporation section cylinder is precision bored and polished

◆ The equipment has a small footprint, simple structure, easy maintenance, and can be matched with the system.

◆ Various types of scraper structures such as membrane column, hinge, fixed scraper, and W-shaped scraper can be selected.

Application

◆ This machine is an evaporator that uses high-speed rotation to distribute liquid into a uniform thin film and performs evaporation or distillation in a vacuum state. It consists of one or more heating cylinders with jackets and a high-speed rotating film scraping mechanism inside the cylinder. The scraping mechanism continuously scrapes the liquid onto the wall of the heating cylinder to form a uniformly thick liquid film and moves downwards. At the same time, the low boiling point components rise, evaporate, and separate, and the concentrated liquid is discharged from the bottom of the evaporator.

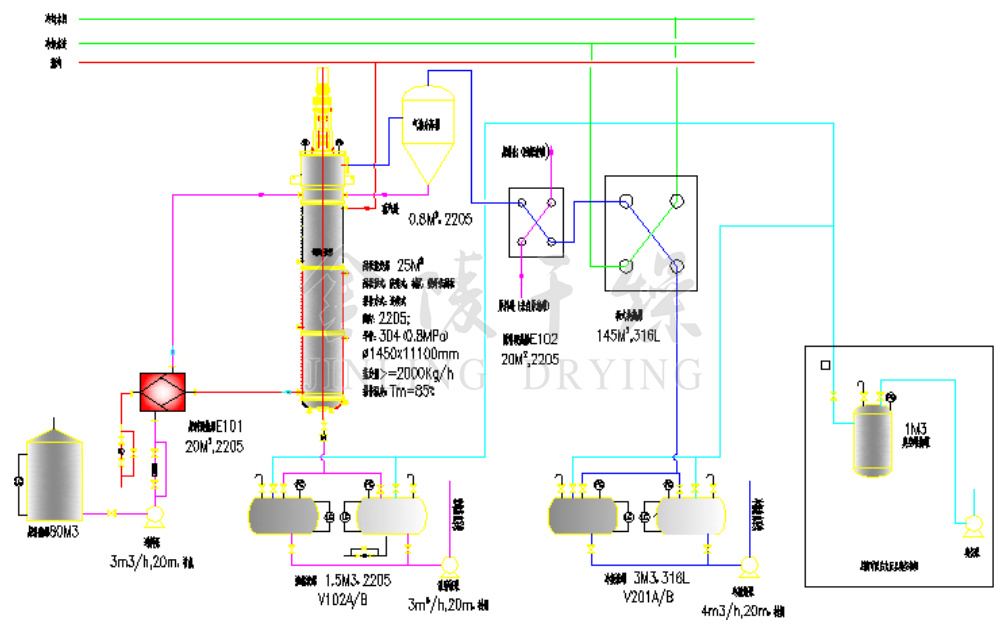

Process Chart

◆ Widely used in the evaporation and distillation of materials containing solid particles, crystallization, polymerization, scaling, etc., it is mainly suitable for industries such as pharmaceuticals, food, light industry, petroleum, chemical, pesticide, biology, environmental protection, etc. It is particularly suitable for the evaporation and concentration of high viscosity, easily scaling, heat sensitive, and high concentration materials.

Technical Specifications

| Model | GBNI | GBN2 | GBN4 | GBN6 | GBN10 | GBN12 | GBN20 | GBN30 | GBN40 |

| Heat exchange area(m²) | 1 | 2 | 4 | 6 | 10 | 12 | 20 | 30 | 40 |

| Steam pressure(MPa) | 0.3 | ||||||||

| Vacuum degree(MPa) | -0.08 | ||||||||

| Evaporation rate(kg/h) | 200 | 400 | 800 | 1200 | 2000 | 2400 | 4000 | 6000 | 8000 |

| Steam consumption(kg/h) | 220 | 430 | 840 | 1260 | 2100 | 2600 | 4800 | 6600 | 8800 |

| Motor power(kW) | 1.5 | 3.0 | 4.0 | 5.5 | 11 | 11 | 15 | 22 | 30 |

| Speed(rpm) | 250 | 250 | 136 | 136 | 88 | 88 | 88 | 43 | 35 |

| Equipment height (reference)(m) | 3100 | 4800 | 5680 | 6410 | 7200 | 7800 | 9850 | 11000 | 12000 |

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.