Spray dryer for waste liquid

Key words

Category

Enquiry

Parameter download

Descriptions

◆Spray drying is a simple drying method that directly processes the liquid phase to the solid phase.

◆It is mainly suitable for drying from solution, lotion, suspension or paste liquid raw materials to produce powder and granular products. Generally, different tower diameters, heights, temperatures, heat sources, dust removal, and supporting accessories are used based on the material status and requirements. Due to its high energy consumption, it is usually suitable for products with high added value or other processes that are difficult to achieve.

Principle

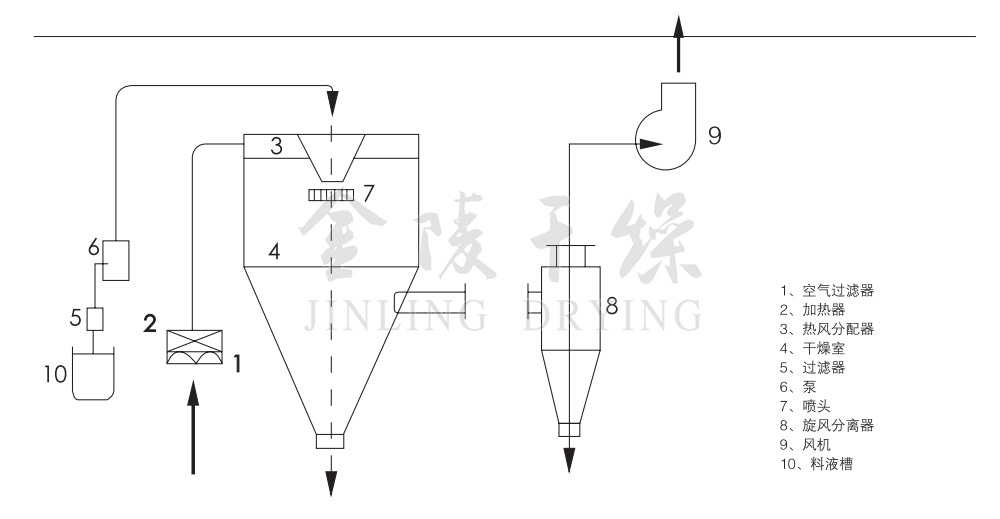

◆After being filtered and heated, the air enters the hot air distributor at the top of the dryer, and the hot air enters the drying chamber uniformly in a spiral shape. The feed liquid is pumped to the high-speed centrifugal atomizer at the top of the tower, where it is atomized into extremely fine mist droplets. When it comes into contact with hot air, the moisture evaporates rapidly in a very short time. The finished product is continuously collected by the dust collector at the bottom of the drying tower, and the exhaust gas is discharged by the fan for further treatment.

Process Chart

Technical Specifications

| Model | LPG | |||||

| 5 | 25 | 50 | 100 | 150 | 200-2000 | |

| Inlet temperature(℃ | 140-350Automatic control | |||||

| Outlet temperature (℃) | 80-90 | |||||

| Maximum evaporation capacity of water(kg/h) | 5 | 25 | 50 | 100 | 150 | 200-2000 |

| Drive type of centrifugal spray head | Electric | Mechanical or electric transmission | ||||

| Speed(rpm) | 25000 | 8000 | 18000 | 18000 | 15000 | 8000-15000 |

| Spray disc diameter(mm) | 50 | 120 | 120 | 120 | 150 | 80-340 |

| Heat source | Electric | Electric | Steam+electricity, fuel oil, gas | Steam+electricity | Steam+electricity, fuel oil, gas | Solved by users themselves |

| Maximum power of electric heating(kW) | 18 | 36 | 60 | 81 | 99 | Determine based on specific circumstances |

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.