SJM Multi-Effect Falling Film Evaporator

Key words

Category

Enquiry

Parameter download

Principle

◆The material liquid is added to the upper part of the heater of the falling filmevaporator through the feeding pump, and after being evenly distributed by the filmdistribution device, it flows evenly downward in the form of liquid film along the innerwall of the heat exchanger tube. The water evaporates Quickly, and the vapor-liquid is fully separated by the separating device.After the secondary steam is condensed,the residualheat can enter the previous system or the following system to continue heating, and the liquid phase is discharged from the separation chamber. This equipment can also be usedin combination with multi-effect, forced circulation, MVR and other evaporators.

Applications

◆The equipment is suitable for continuous evaporation and concentration of milk, juice,biochemical products, pharmaceutical products, seasonings, food additives, and industrialwastewater.

◆The machine has the characteristics of high heat transfer efficiency, small temperature.

◆The evaporation temperature is low, and the efficiency and evaporation temperaturecan be determined according to the requirements of our customers.

◆The top spraying film device of the heating evaporator is unique, and the filmformation is uniform.

◆The condenser has a unique structure, a large heat transfer coefficient, and good performance.

◆The use of injecting hot pressure pump has obvious energy saving effect.

◆Depending on the requirements of our customers , either the automatic control modelor the manual control model can be applied.

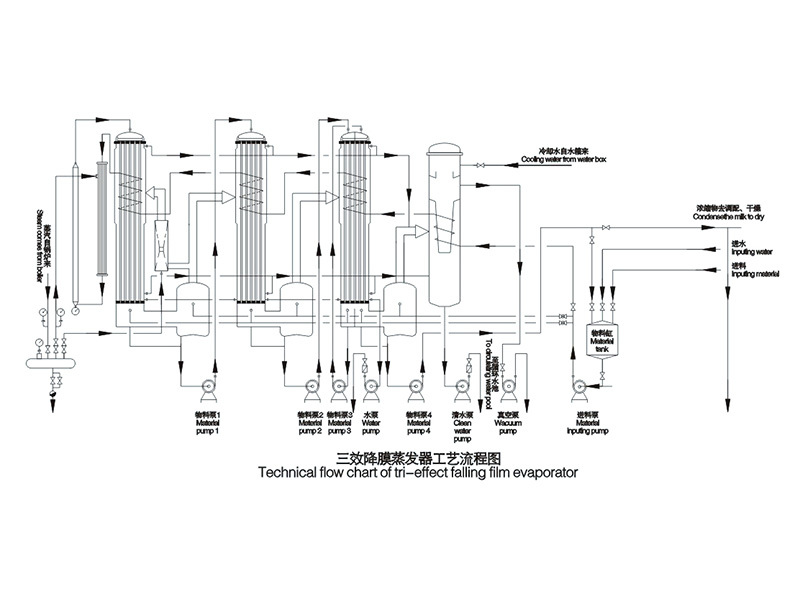

Process Chart

Technical Specifications

|

Model |

SJM500 |

SJM1000 |

SJM1500 |

SJM2000 |

SJM3000 |

SJM5000 |

SJM6000 |

SJM8000 |

|

|

Evaporation Capacity (kg/h) |

500 |

1000 |

1500 |

2000 |

3000 |

5000 |

6000 |

8000 |

|

|

Pressure(MPa) |

0.1-0.25 |

||||||||

|

Steam Consumption (kg/h) |

185 |

370 |

555 |

740 |

1110 |

1850 |

2220 |

2960 |

|

|

Circulation Water Consumption (T/h) |

S |

10 |

13 |

15 |

18 |

25 |

30 |

40 |

|

|

Weight |

2060 |

2480 |

3280 |

4200 |

4860 |

5770 |

6430 |

7600 |

|

|

Overall Size (Reference) (mm) |

7080×900×3500 |

7680×1000×4000 |

8380×1100×4600 |

8890×1200×4600 |

9500×1300×4900 |

10200×1400×5300 |

10800×1500×5800 |

11500×1600×5800 |

|

|

|

Vacuum Level (Absolute Pressure) (MPa) |

|

Evaporation Temperature (℃) |

||||||

|

Single Effect |

-0.048~-0.057 |

Evaporation Temperature (℃) |

|||||||

|

Double Effect |

-0.031~-0.038 |

70-75 |

|||||||

|

Triple Effect |

-0.019~-0.025 |

60-65 |

|||||||

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.