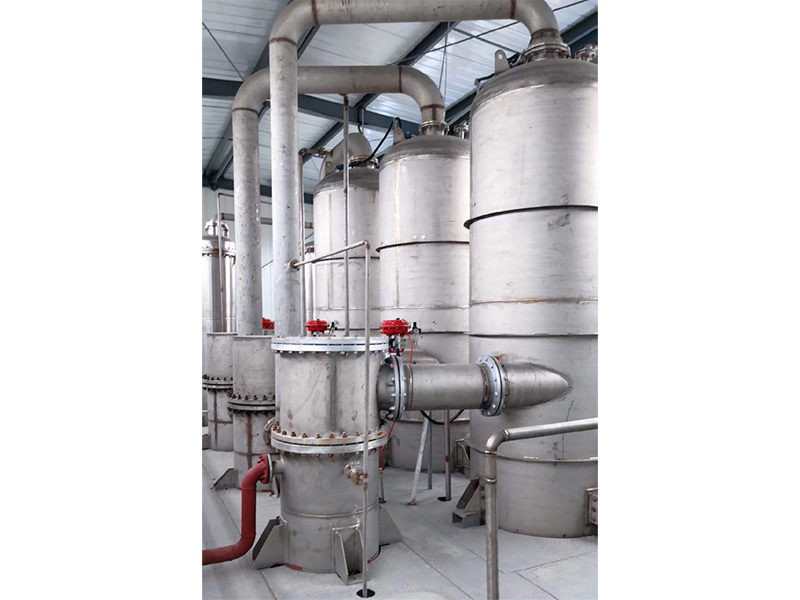

SZ Multi-Effect Evaporator

Key words

Category

Enquiry

Parameter download

Principle

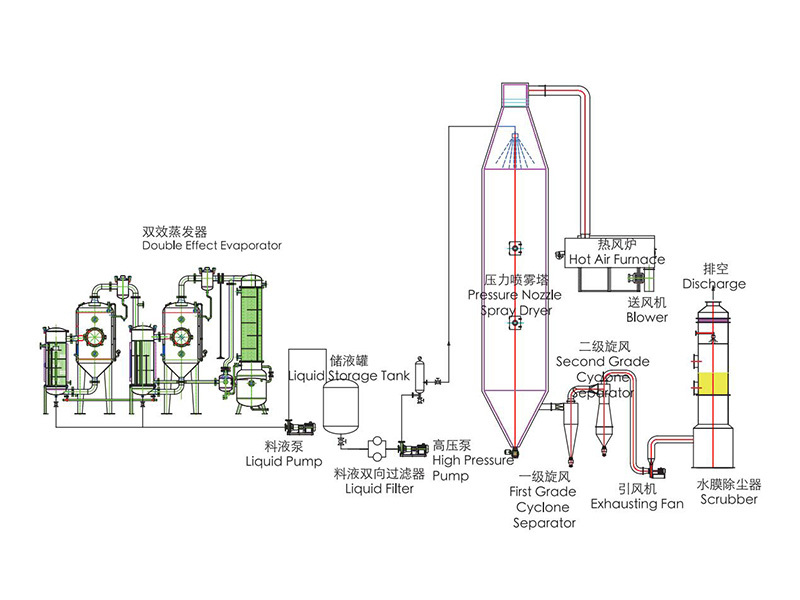

◆The multi-effect evaporation eouipment uses new steam for heating during the single effect. The secondary steamgenerated is reused for the double effect.This step will be repeated for further use of thermal energy. The feed liouidis concentrated during the multi-stage heating and evaporation process,which reduces the operating cost at the same time.

Applications

◆Evaporation and concentration of traditional Chinese medicine,western medicine. glucose,products forenvironmental protection, dairy. chemicals, industrial wastewater and other solutions; especially suitable for operationat low temperature.

Features

◆Significant energy-saving benefits: Compared with the single-effect, external-circulation evaporator based onModel 1000, it saves 5,400 tons of steam, 140,000 tons of water, and 130,000 kWh of electricity annually.

◆The combination of natural, external heating and negative pressure evaporation will accelerate the evaporationand increase the concentration ratio up to l.2-I.3.

◆The three-effect simultaneous evaporation is used, and the secondary steam is recycled, which not only saves theinvestment of the boiler, but also saves energy consumption.Compared with the single-effect concentrator, the energyconsumption is reduced by 70%.

◆Multifunctional operation features: (l) single effect, double effect and triple effect can be repeated while the panscan be used to collect the paste; (2) intermittent and continuous feeding; (3) the concentrated mother liquor can bedirectly dried into solids through a complete set of equipment.

◆The parts in contact with the material are made of high-quality stainless steel, which meets GMP standards. Theheater and evaporator of this equipment are all equipped with a heat insulation layer. The surface of the insulationlayer is made of stainless steel plate.

Technical Specifications

|

Model |

SZ500 |

SZ1000 |

SZ1500 |

SZ2000 |

SZ3000 |

SZ5000 |

SZ8000 |

||

|

Evaporating Capacity (kg/h) |

500 |

1000 |

1500 |

2000 |

3000 |

5000 |

8000 |

||

|

Vapor Pressure(MPa) |

< 0.25 |

||||||||

|

Steam Consumption (kg/h) |

≤200 |

≤400 |

≤600 |

≤800 |

≤1200 |

≤2000 |

≤3200 |

||

|

Evaporating Temperature (℃) |

Single Effect |

85-95 |

|||||||

|

|

Double Effect |

70-80 |

|||||||

|

|

Triple Effect |

55-65 |

|||||||

|

Vacuum Level (MPa) |

Single Effect |

-0.02~-0.04 |

|||||||

|

|

Double Effect |

-0.05~-0.06 |

|||||||

|

|

Triple Effect |

-0.08~-0.09 |

|||||||

|

Circulation Water Consumption (T/h) |

10 |

18 |

25 |

35 |

50 |

85 |

135 |

||

|

Concentrating Ratio |

1.2-1.3 |

||||||||

|

Vessel Type |

Category Ⅰ |

||||||||

|

Overall Size(Reference)(L×W×H) |

5×1.3×3 |

6.5×1.5×3.3 |

7×1.7×3.5 |

7.5×2×4 |

7.8×2×4 |

8×2×4.5 |

9×2.5×5 |

||

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.