Extract Spray Dryer

Key words

Category

Enquiry

Parameter download

Descriptions

◆The extract spray dryer is mainly used for drying products with low melting point and high sugar content. It can be equipped with air dehumidifier, automatic cleaning device, air filtration system, cold wall system, windfilm system, exhaust gas treatment system and other devices. The machine has a high level of automation and the operation of this machine is very easy. This machine is generally made of stainless steel and it meets the reQuirements of "GMP".

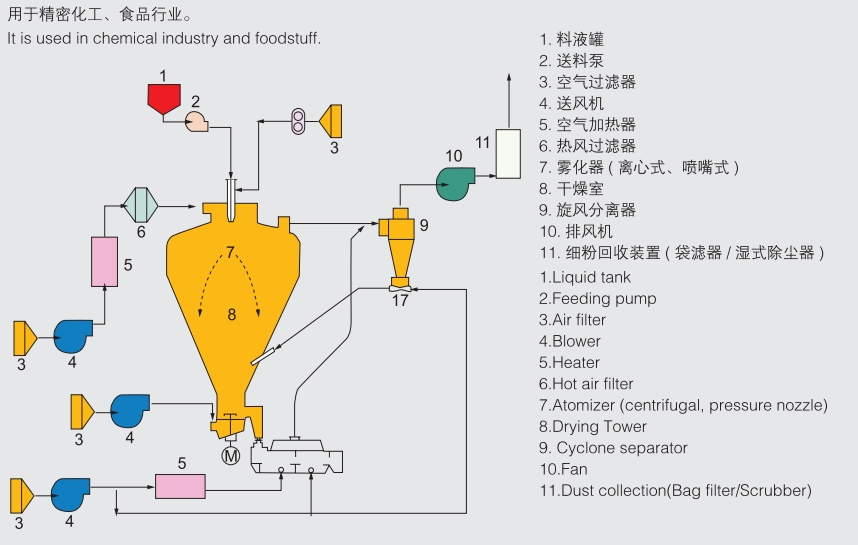

Principle

◆After the air is filtered and heated, it enters the hot air distributor at the top of the dryer. Once the hot air passes the distributor, it enters the drying chamber evenly along the spiral trajectory. The liquid material is pumped to the high- speed centrifugal atomizer at the top of the tower, and it is atomized into very fine mit-like droplets. Once it is in contact with the hot air, the water evaporates rapidly, and the product can be dried within a very short amount of time. The finished product is continuously collected by the dust collector and stored inside the receiver. The exhaust gas is discharged by the induced draft fan.

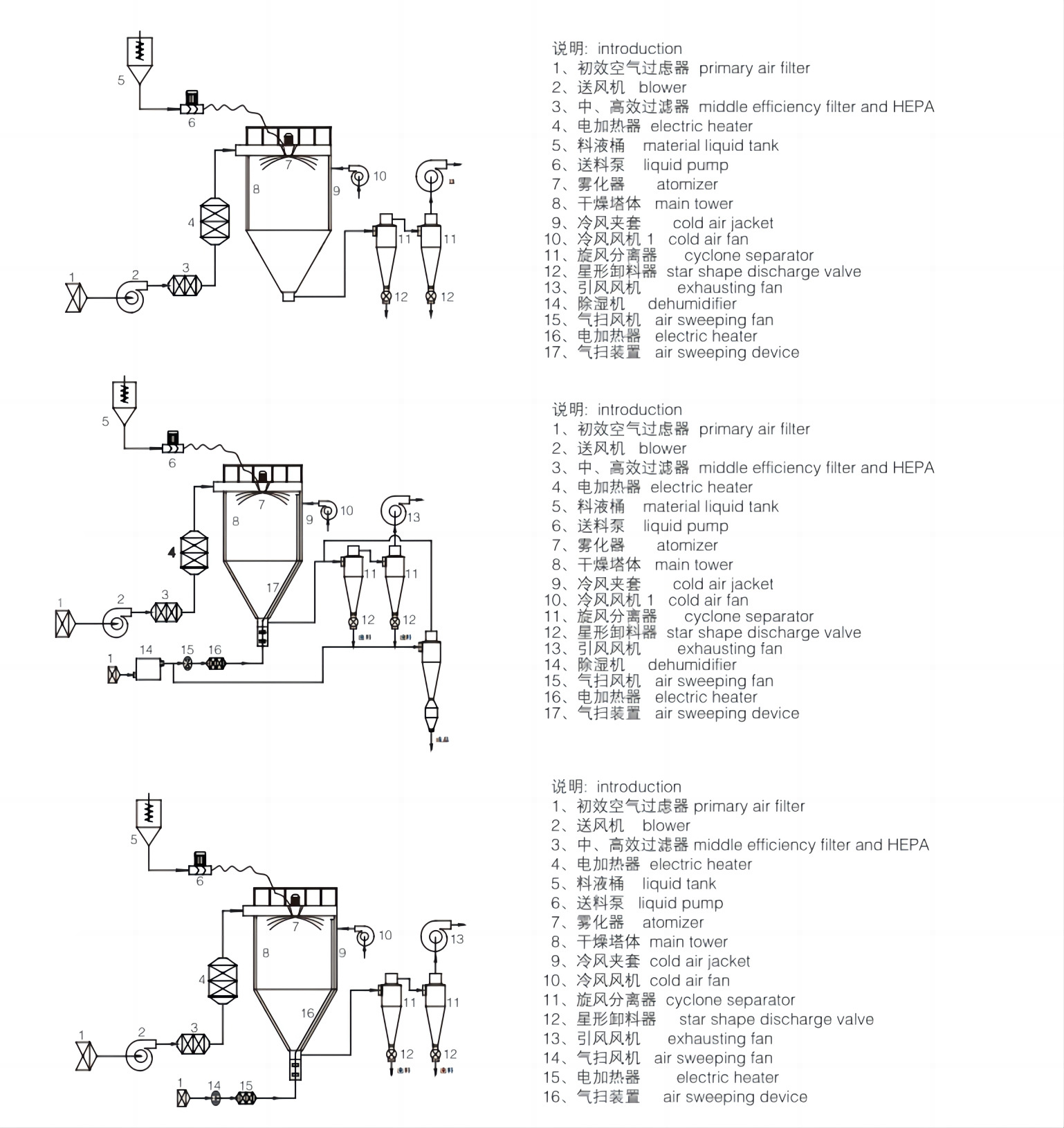

Features

◆The main body of the tower is equipped with a cold air jacket to make it less likely for the material to stick to the wall.

◆The main body of the tower has an automatic vibration device or a wall sweeping device.

◆The main body of the tower and the piping system have openings for cleaning and discharging sewage.

◆The feeding tank can have the automatic control function for constant temperature.

◆Accessories for high-pressure automatic cleaning system are available.

◆PLC touch screens and DCS control systems can be added to the eQuipment.

◆Two-s-stage cyclone dust cllector, or one stage cyclone dust cllector plus wet dust cllector can be used for material collection. .

◆The atomizer can be equipped with variable frequency speed control.

◆The machine is equipped with the triple effect filter for air purification standard up to level 100,000-300,000.

◆Air dehumidifier, cooler and vibrating screen are also available.

Structure Diagram

Technical Specifications

| Model | ZLPG-25 | ZLPG-50 | ZLPG-80 | ZLPG-100 | ZLPG-150 | ZLPG-200 | ZLPG-300 | ZLPG-300~5000 |

| Evaporated Moisture (kg/h) | 25 | 50 | 80 | 100 | 150 | 200 | 300 | Depending on the situation |

| Treatment Capacity of Raw Liquid Material(kg/h) | 25~34 | 50~68 | 80~108 | 100~135 | 150~203 | 200~270 | 300~406 | |

| Output of Product(kg/h | 4.8~7.2 | 9.2~14 | 14.8~22.4 | 18.4~28 | 28~42 | 36.8~56.4 | 55~85 | |

| Solid Content Of Raw Wet Material(%) | 18~25 | |||||||

| Moisture Content of Product (%) | 3~5 | |||||||

| Power(kW) | 63 | 99 | 132 | 153 | 204 | 246 | 330 | |

| Heating Source | Steam Plus Electricity | |||||||

| Collecting Method and Efficiency | Two-stage cyclone dust collector or one-stage cyclone dust collector plus one-stage wet dust collector 95% | |||||||

| Automatic Control Meters and Instruments | Indicators for the temperature of the hot air and the temperature of the exhaust gas, automatic tem- perature controller |

|||||||

| Temperature of Inlet Air(℃) | 150~200 | |||||||

| Temperature of Outlet Air (℃) | 80~100 | |||||||

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.