Belt Dryer

Key words

Category

Enquiry

Parameter download

Principle

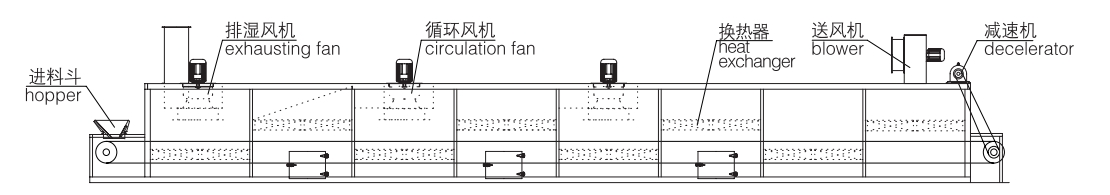

◆The material is evenly spread on the mesh belt by the feeder. The mesh belt is generally made from 12 -60 mesh stainless steel wire, which is dragged and moved in the dryer by the transmission device. The dryer is composed of several units, and each unit is independently heated by the circulation of hot air. The hot air passes through the mesh belt covered with the material from bottom to top or from top to bottom, in order to complete the process of heat conduction and mass transfer. During this process, the water contained in the materialis removed, and some of the exhaust gas is discharged by the dehumidifying fan. The mesh belt moves slowly inside the chamber, and the moving speed can be adjusted according to the moisture level of the material. The number of the circulation units for drying and the number of the layers can be determined according to the requirements of our customers.

Features

◆linling is a professional manufacturer of belt dryer In 2016, our company produced the belt dryer that is designed with our innovations for processing graphene specifically, and the application of this dryer achieved great success.

◆This machine is widely used for drying materials with good air permeability such as flakes, strips and granules. It is particularly suitablefor materials that have high moisture content, but require low drying temperature, such as dehydrated vegetables, and Chinese herbal medicines.

◆These dryers have the advantages such as fast drying speed, high level of automation and low energy consumption.

◆For materials such as sludge and filter cake, they need to be granulated before being uniformly dried.

◆Depending on the material, different heating, air distribution, feeding and circulation methods can be selected. Diferent materials such as wire mesh, conveying chain mesh, non-stick mesh belt, PTFE mesh belt, punching mesh plate can be used for making the mesh belt.

◆According to the requirements of our customers , optional cleaning device, sweeping device, distributing device and dust removal device can be added to the dryer.

Flow Chart

Technical Specifications

| Model | 1.2-8 | 1.2-10 | 1.6-8 | 1.6-10 | 2-8 | 2-10 |

| Unit number | 4 | 5 | 4 | 5 | 4 | 5 |

| Belt width(m) | 1.2 | 1.2 | 1.6 | 1.6 | 2 | 2 |

| Drying section length (m) | 8 | 10 | 8 | 10 | 8 | 10 |

| Thickness of the material(mm) | 10-80 | |||||

| Temperature(℃) | 60-150 | |||||

| Steam pressure(Mpa) | 0.2-0.8 | |||||

| Steam consumption(kg/h) | 120-300 | 150-375 | 150-375 | 170-470 | 180-500 | 225-600 |

| Drying time(h) | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 |

| Drying strength (kgH,O/h) | 60-160 | 80-220 | 75-220 | 95-250 | 100-260 | 120-300 |

| Total power of the blower(kw) | 8.8 | 11 | 12 | 15 | 16 | 20 |

| Total power of the dryer(kw) | 10.1 | 12.3 | 13.3 | 16.3 | 17.3 | 21.3 |

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.