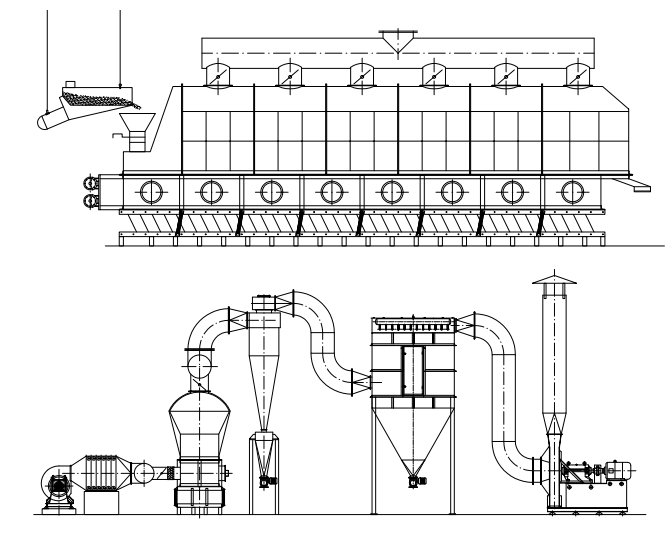

Dual-Mass Vibrating Fluidized Bed Dryer

Key words

Category

Enquiry

Parameter download

Principle

◆On the basis of foreign technology, our company has developed and produced the dual-mass fluidized bed drying device, which is mainly composed of the lower chamber, the middle chamber, the upper chamber, the base, the plate of the fluidized bed, the spray hole, the vibration system, the feed receiving system, the system of the forced draught blower induced draft fan, etc. The box-type vibrator is equipped with two vibration motors, which generate a horizontal excitation force through the rotation of the eccentric block. Due to the effect of the spring (resonance spring), a vertical component force and a horizontal component force are generated. The vertical component force and the pressurized hot air which comes through the spray hole will toss the material on the bed plate, so that the material will be in a fluidized state; the horizontal component force can make the material move forward evenly at a certain speed (wind speed, layer thickness, and discharge speed can be adjusted), the material is discharged through the overflow weir and the discharge hopper, and the drying operation is completed.

Features

◆The thickness of the material layer can be determined according to the characteristics of the material; the adjustment is generally within≤300mm, so that the retention time can be extended significantly.

◆The thickness and aperture of the bed plate can be determined based on the size and wind speed of the equipment.

◆There are a variety of options for the structures of the spray holes on the bed surface.

◆The elastic supporting structure can be used to increase the area of the drying bed, and reduce the installed power of vibration in the middle chamber.

◆It is especially suitable for drying or cooling large sticky powder materials of large and continuous batches.

◆In 2009, our company designed and produced 5 sets of dual-mass vibrating dryers for processing citric acid specifically with our own innovations, and the application of this dryer achieved great success. We also made a groundbreaking improvement on our designed and used imported pneumatic spring for damping, which significantly reduced the noise and increased the service life of the equipment.

Applications

◆For drying and cooling materials with low viscosity such as citric acid, sodium sulfate, polyacrylamide.

Structure Diagram

Technical Specifications

| Model | Fluidized Bed Area | Inlet Air Temperature | Outlet Air Temperature | Evaporated Moisture | Vibration Motor Power |

| SLG 2x10 | 20 | 120~140 | ~70 | 300-850 | 5.5x2 |

| SLG 2x18 | 36 | 120~140 | ~70 | 600-1500 | 11x2 |

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.