Enhanced Flash Dryer

Key words

Category

Enquiry

Parameter download

Applications

◆ This machine is applicable for drying materials shaped like filter cakes with relatively high moisture content, such as copolymer of vinyl acetate and vinyl chloride, floc of cellulose acetate fiber, catalyst, CMC, calcined gypsum, electrolytic manganese dioxide, ammonium anthraquinone sulfonate. fluorspar, diatomite, silica gel catalyst, bone meal, drugs with potassium perchlorate sulfa, synthetic resin, activated gluten, activated clay, chemical filter cake. rutile titanium dioxide, sebacic acid, aluminum sulfate, calcium phosphate, starch of phosphate esterification, dyes, calcium citrate, slime, clay. aluminum hydroxide, barium hydroxide, calcium lactate, yanuric acid, lime, biological products, calcium carbonate slurry, sludge, aluminum stearate, organic dyes, corn gluten feed, mica powder, medicaments, pigments, beer residuals, etc.

Principle

◆The enhanced flash dryer is designed based on the traditional flash dryer. It has an additional set of the intensifying disperser with the frequency control function. After the wet material enters the intensifier through the spiral feeder, it is fully mixed with the hot airflow. Under the impact and propulsion of the blades that rotate rapidly, the material is broken into fine particles, and it moves towards the outlet as being dried at the same time. This way, the material can be dried evenly. The wet and heavy particles that cannot be lifted will continue to settle, and they will be crushed and dried again until they can be lifted. The dried material is continuously discharged after being collected by the cyclone separator, and the wet air is discharged through the induced draft fan. The cloth bag dust collector or the water film dust collector can also be added to the machine.

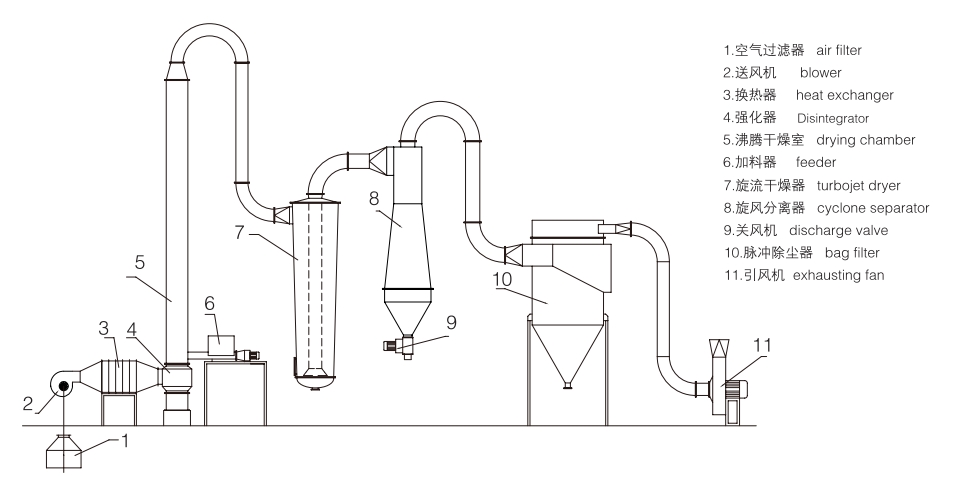

Flow Chart

Technical Specifications

| Model | Evaporated Moisture (Approximate)(kg/h) | Power (kW) | Floor Space Reouired (m²) | Height ((m) |

| JG 50 | ~50 | ~10 | ~20 | ~9 |

| JG 100 | ~100 | ~20 | ~32 | ~11 |

| JG 200* | ~200 | ~31 | ~40 | ~11 |

| JG 250 | ~250 | ~32 | ~64 | ~13 |

| JG 500 | ~500 | ~54 | ~96 | ~13 |

| JG1000* | ~1000 | ~135 | ~120 | ~15 |

| JG 1500* | ~1500 | ~175 | ~200 | ~16 |

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.