Centrifugal Spray Dryer

Key words

Category

Enquiry

Parameter download

Descriptions

◆Spray drying is the simplest way to turn the liuid phase directly to the solid phase. It is mainly used to make powdery and granular products fromsolutions, emulsions, suspensions or pasty liquid materials. Generally, we use different tower diameters, heights, temperatures, heat sources, dust removal devices and other accessories according to the conditions and the requirements of the material. Since the energy consumption of this equipment is very high, it is usually applicable for the products with high potential value or the productsthat are difficult to make using other processing techniques.

Features

◆The surface area of the liquid material increases significantly after atomization. During the hot air convection drying process, the moisture evaporates instantly, and the drying process only requires a few seconds. This equipment is especially suitable for the drying heat- sensitive materials. Different feeding pumps are available such as peristaltic pumps and screw pumps.

◆The product of this machine will have good uniformity, fluidity and solubility. This machine needs to be customized for materials with high viscosity.

◆The operation of this machine is automatic and continuous. The process is easy to control. The maintenance is very convenient.

◆The particle size, bulk densit, and moisture content of the product can be adjusted appropriately by changing the operating conditions within a certain range.

◆The transmission of the atomizer can be electric or mechanical. We can also add the multi-stage filtration to collect or wash the exhaust gas.

◆Materials that are easy to corrode, wear, crystallize, or melt, materials that are flammable or explosive, and materials with high viscosity must be specified before any orders are made.

◆The heat source can be steam, electric heating, hot blast stove, etc. The material of the machine can be determined according to the requirements of our customers.

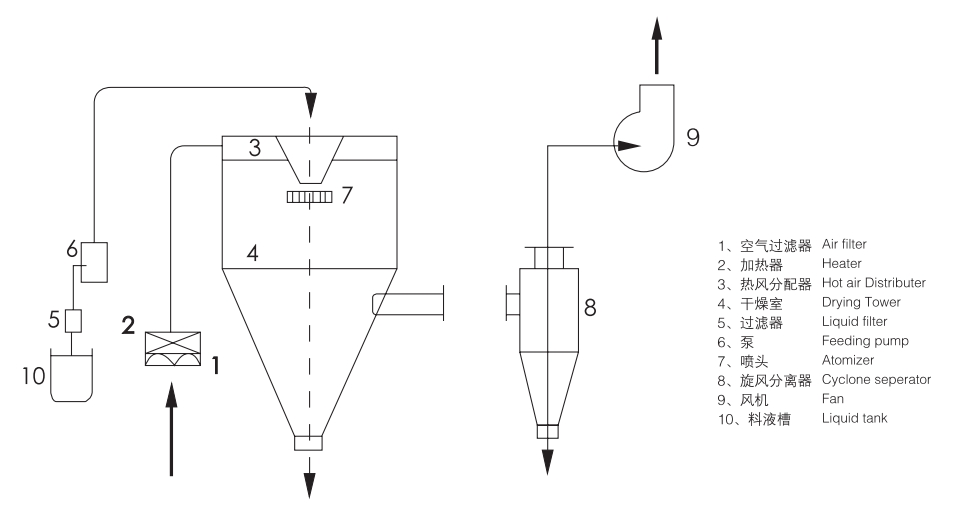

Principle

◆After the air is filtered and heated, it enters the hot air distributor at the top of the dryer. Then, the hot air enters the drying chamber evenly along the spiral trajectory. The liquid material is pumped to the high- speed centrifugal rotary atomizer at the top of the tower, and it is atomized into very fine mit-like droplets. Once it is in contact with the hot air, the water evaporates rapidly within a very short amount of time. The finished product is continuously collected by the dust collector at the bottom of the drying tower. The exhaust gas is discharged by the fan.

Flow Chart

Technical Specifications

| Model | LPG | |||||

| 5 | 25 | 50 | 100 | 150 | 200-2000 | |

| Inlet Air Temperature(℃) | 140-350140-350 Automatically controlled | |||||

| Outlet Air Temperature(℃) | 80-90 | |||||

| Max Capacity of Evaporation (kg/h) | 5 | 25 | 50 | 100 | 150 | 200-2000 |

| Transmission Method of Centrifugal Atomizer | Electrical Transmission |

Mechanical and Electrical Transmission | ||||

| Rotation Speed (rpm | 25000 | 18000 | 18000 | 18000 | 15000 | 8000-15000 |

| Diameter of Atomizer (mm) | 50 | 120 | 120 | 120 | 150 | 180-340 |

| Heat Source | Electricity | Electricity | Electricity + Steam Fuel, Gas |

Electricity + Steam |

Electricity + Steam, Fuel, Gas |

Determined by customer |

Max Electrical Heating Power (kW) |

18 | 36 | 60 | 81 | 99 | Depending on the situation |

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.