Vibrating Fluidized Bed Dryer

Key words

Category

Enquiry

Parameter download

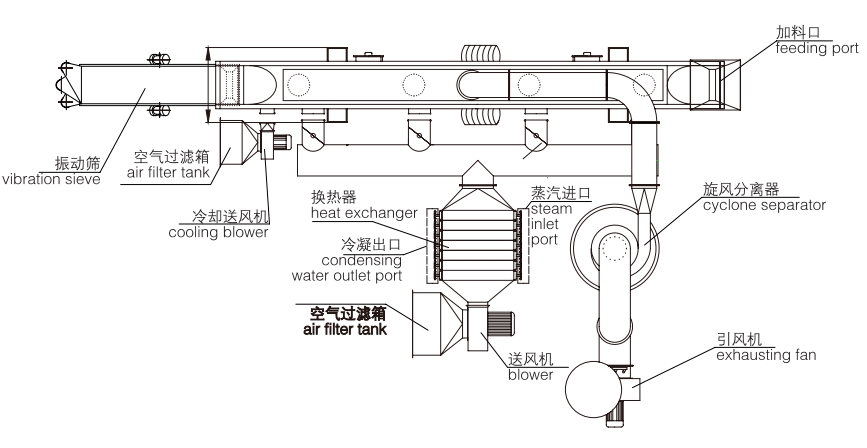

Principle

◆The material enters the machine evenly from the feed inlet. Due to the vibration force, the material is tossed forward continuously in the horizontal direction. After the hot air passes through the bed hole and exchanges heat with the wet material, the wet air is removed by the separator and then discharged from the exhaust outlet; dry material is discharged from the discharge outlet.

Features

◆linling Company is a professional manufacturer of vibrating fluidized bed dryer.

◆The height of the fluidization chamber, the thickness of the material layer, the structure of the bed hole and the method of dust collection can be determined based on the characteristics of the material.

◆The machine is driven by a vibration motor and it runs smoothly; the damper can be equipped with imported airbags or rubber springs.

◆The thermal eficiency of the machine is high; the bed temperature is adjustable; the fuidization is uniform; no corner is missed.

◆The thickness of the material layer, the moving speed inside the machine, and the amplitude of vibration can be adjusted within the design scope; the machine has wide applications.

◆The machine will do less damage to the surface of the material comparatiely; it suitable for drying or cooling powder and granular materials; a variety of orifice plates are available.

◆The machine is operated continuously in a sealed environment; optional devices are available, such as air dehumidifier, multi-stage filtration device, different dust removal devices, cooling device, screening device,weighing device, packaging device, etc. .

◆For mass production of materials with high moisture level, multi-stage series connection can be used to improve the drying eficiency.

◆Based on the requirements of our customers,we can provide designs such as air intake by sections, online screening, easy cleaning, vibration structure, adjustment and control of the material layer, etc.

Technical Specifications

| Model | Fluidized Bed Area(m2) | Inlet Air Temperature(℃) | Outlet Air Temperature(℃) | Evaporated Moisture(kg/h) | Vibration Motor Power(kW) |

| ZLG0.30×3 | 0.9 | 120~140 | ~70 | 20-35 | 0.75×2 |

| ZLG0.45×4.5 | 2.025 | 120~140 | ~70 | 50-70 | 1.1×2 |

| ZLG0.45×6 | 2.7 | 120~140 | ~70 | 80-100 | 1.1×2 |

| ZLG0.6×6 | 3.6 | 120~140 | ~70 | 100-130 | 1.5×2 |

| ZLG0.75×6 | 4.5 | 120~140 | ~70 | 120-170 | 1.5×2 |

| ZLG0.9×6 | 5.4 | 120~140 | ~70 | 140-170 | 2.2×2 |

| ZLG0.6×7.5 | 4.5 | 120~140 | ~70 | 130-150 | 2.2×2 |

| ZLG0.75×7.5 | 5.625 | 120~140 | ~70 | 150-180 | 3.0×2 |

| ZLG0.9×7.5 | 6.75 | 120~140 | ~70 | 160-210 | 3.0×2 |

| ZLG1.2×7.5 | 9 | 120~140 | ~70 | 180-270 | 3.7×2 |

| ZLG1.5×7.5 | 11.25 | 120~140 | ~70 | 180-500 | 3.7×2 |

| ZLG1.8×9 | 16.2 | 120~140 | ~70 | 180-500 | 4.0×2 |

| ZLG2.0×12 | 24.0 | 120~140 | ~70 | 400-800 | 5.5×2 |

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.