Rotating Double-Cone Vacuum Dryer

Key words

Category

Enquiry

Parameter download

Description

◆This model is a combination of mixing (itering) and drying. It uses cylinder rotation and jacket heating structure for heating. Accessories such as buffer tank, condenser, vacuum pump can also be equipped to form a vacuum drying system. The eQuipment has a simple structure, which makes it convenient to clean, and easy to operate. It is widely used for drying materials across the pharmaceutical, chemical, food, dyeing and other industries.

Principle

◆SZG rotating double-cone vacuum dryer is a double-cone rotary tank. Under the vacuum condition, the jacket is heated by the medium added to the system. The heat is conducted through the inner wall of the tank and the wet material. The water evaporated will be discharge by vacuum pump. Due to the vacuum state inside the tank, the material constantly movesinwards and outwards as the tank rotates. The drying eficiency of the material is improved in this case, in order to fulfill the purpose of low temperature drying.

Applications

◆This machine is applicable for drying powder or granular materials that are easy to flow but are not easy to agglomerate or stick.

◆For flammable and explosive materials, drying method and steam heating method (the pressure vessel certificate should be issued) should be specified.

◆If hot water or thermal oil is used, it should be stated before any orders are made.

◆If GMP requirements are applied, solvent recovery equipment and other supporting components will be discussed separately.

◆For material that involves stainless steel inside or outside, or enamel on the inner wall. The jacket is usually carbon steel if not specified otherwise.

◆It is recommended to use speed control with frequency conversion for the models that are above 1000; boring technique will be used to process the shaft hole.

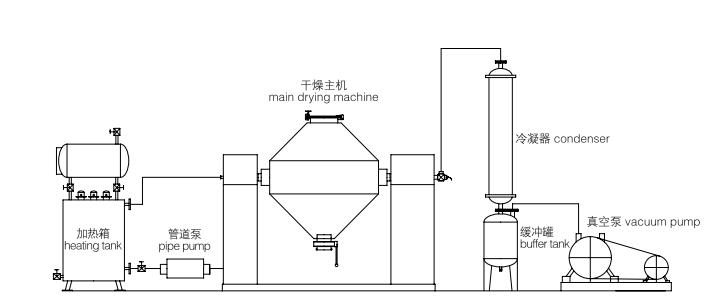

Process Flow Chart

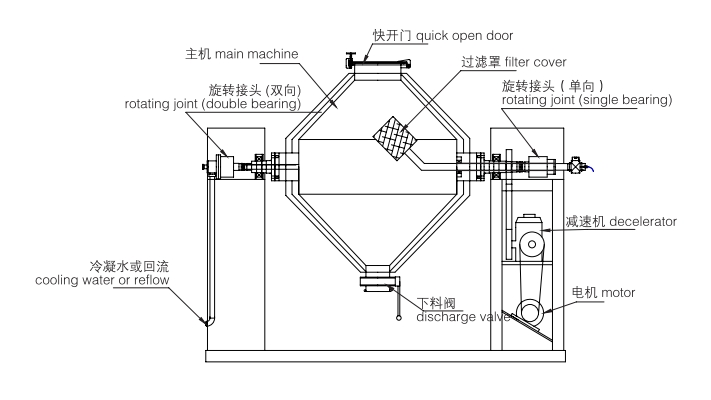

Structure Diagram

Model 6000 Large Scale Enamel Rotary Dryer Model 3000 Stainless Steel Rotary Dryer Model 5000 Stainless Steel Rotary Dryer

Technical Specifications

| Item | Unit | Model | ||||||||||||

| Name | 100 | 200 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 | 6000 | 8000 | |

| Total Volume | L | 100 | 200 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 | 6000 | 8000 |

| Operational Volume | L | 50 | 100 | 175 | 250 | 375 | 500 | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 |

| Heating Area | 32 | 1.16 | 1.5 | 2 | 2.63 | 3.5 | 4.61 | 5.58 | 7.5 | 10 | 12 | 14 | 16 | 20 |

| Rotation Speed | r/min | 6 | 4 | 4 | 3 | 1-2 | ||||||||

| Power | kW | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 |

| Frame Height | mm | 1810 | 1910 | 2090 | 2195 | 2500 | 2665 | 2915 | 3055 | 3330 | 3800 | 4200 | 4500 | 5200 |

| Design Pressure inside Chamber | MPa | -0.09-0.096 | ||||||||||||

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.