Paddle Dryer

Key words

Category

Enquiry

Parameter download

Principle

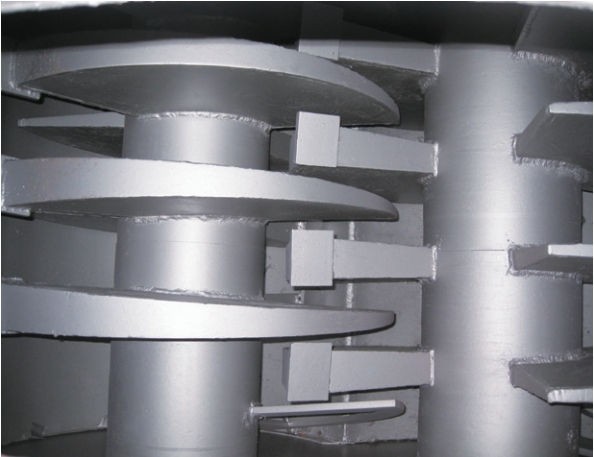

◆Jinling is a professional manufacturer of paddle dryer. The paddle dryer with the wedge structure is one of the first traditional dryers in China. It is a low speed mixing dryer that uses heat conduction. The drying barrel is equipped with a jacket. The hollow shaft is equipped with a hollow paddle, wherea heat transfer medium can flow through. The wet material can exchange heat with the barrel and the hot surface of the paddle through the agitation of the mixing paddle, so that the wet material can be dried eventually. Generally, the structure can be horizontal, double shaft or Quadruple shaft.

◆The company has made a series of improvements in terms of transmission, thermal expansion, blade structure, welding method, sealing, etc.. for better performance and longer service life.

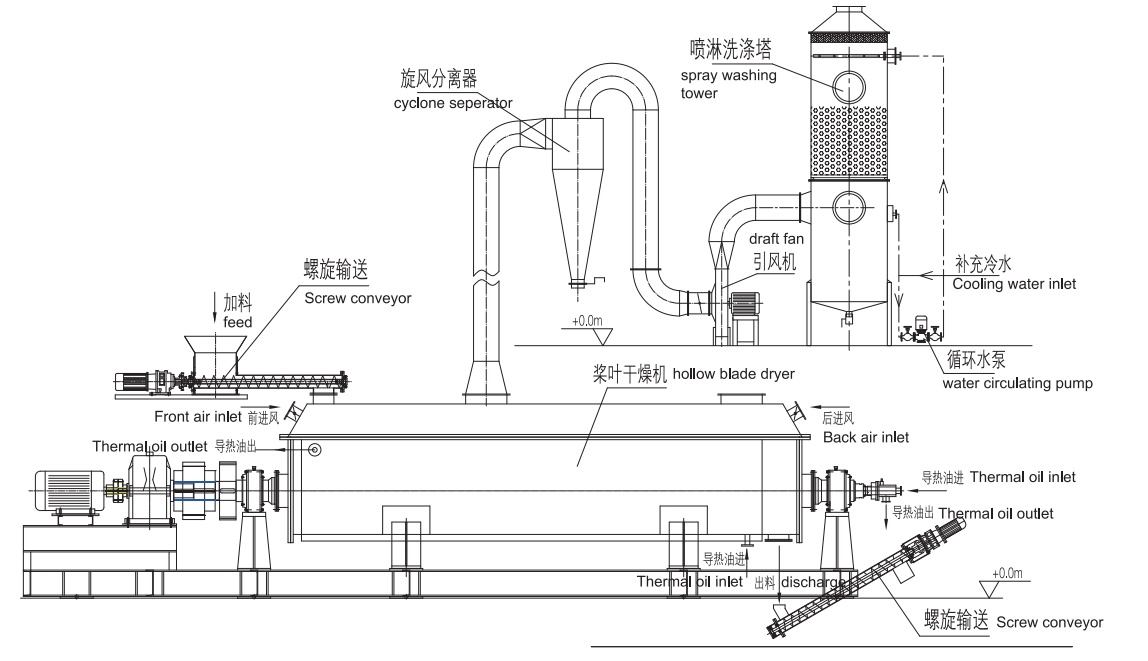

Layout Diagram of Paddle Dryer

| Configuration | Double Shaft | Four Shaft | |||||||||

| Model | 5 | 15 | 20 | 40 | 60 | 90 | 100 | 120 | 150 | 200 | 240 |

| Heating Area (m2) | 5 | 15 | 20 | 40 | 60 | 90 | 100 | 120 | 150 | 200 | 240 |

| Power of Main Motor (kW) | 4 | 15 | 18.5 | 30 | 45 | 55 | 75 | 90 | 110 | 150 | 180 |

| Note | Depending on the characteristics of the raw material and the drying requirements, different materials and configurations will be used for the machine. | ||||||||||

Features

1.The heat required for drying is mainly provided by the wall of the hollow paddle istalled on the hollow shaft, while the heat conduction through the surface of the jacket is very limited comparatively. Therefore, the heat exchange area per unit volume of the eQuipment is large and the floor space required is small.

2.The machine uses heat conduction as the processing method. The entire heat exchange surface is covered by the material to reduce heat loss. The heat utilization rate is above 85%.

3.The paddle has the structure that consists of the inclined concentric reducers. This structure has a certain amount of extrusion and dispersion ability, and it can improve the heat conduction performance of the paddle. The dispersing force due to the combined movement of filter cake or powder particles driven by the inclined surface of the rotating paddle makes it easier for the materials attached to the heating surface to fall off. Also, since the double shaft paddle rotate reversely and expand alternately by sections, it has the function of mixing and cutting, in which case the drying eficiency can be improved significantly.

4.This equipment allows continuous and completely sealed environment for operation, which can reduce the amount of labor required and reduce dust emission as well.

5.The exhaust gas treatment system generally uses negative pressure, with cyclone separator, cloth bag or water film dust scrubber, to reduce the volume of exhaust gas and reduce dust emission as well.

6.The paddle is connected with concentric reducers. It has the upper layer and the lower layer. The paddle angle is so small that there is not enough pushing force. Welding of the paddle may cause isues such as corrosion and leakage. Also, the overall eQuipment is designed to be inclined and it has uneven stress. high resistance and high maintenance rate. Therefore, the size of the eQuipment should not be large.

Technical Specifications

| Name of Material | Temperature of Steam or Thermal Oil | Rotation Speed(rpm) | Feeding Moisture (%) | Product Moisture(%) |

| Distilled Grain | 0.3 | 5 | 84.1 | ≤5 |

| OxytetracyclineResiduals | 0.3 | 5 | 66.3 | ≤5 |

| Coal Ash | 0.4 | 15 | 36 | ≤1 |

| Diatomite | 0.5 | 10 | Petrol Recovery 60 | 1 |

| Kaolin | 0.4 | 3 | 40 | 1 |

| Iron Oxide Monohydrate | 0.3 | 4 | 44 | 1 |

| PPO | 0.3 | 2 | Petrol Recovery 60 | ≤0.5 |

| Magnesium Trisilicate | 0.5 | 5 | 60 | ≤2 |

| Aluminum Oxide | 0.3 | 5 | 33-37 | ≤2 |

| Mycelium | 0.3 | 5 | 38.3 | ≤5 |

| Nitroaniline | 0.3 | 3 | 6.5 | ≤0.7 |

| Sludge | 0.6 | 6 | 80 | 35 |

| Sodium Cyanide | 0.5 | 8 | 11 | 0.3 |

| Cartap | 0.3 | 5 | 21.8 | ≤2.5 |

| Ferrous Sulfide | 0.5 | 4 | Removal of Crystal Water | <1 |

| Cuprous Sulfide | 0.5 | 3 | Removal of Crystal Water | <1 |

| Monosodium Phosphate | 0.3 | 5 | Removal of Crystal Water on the Surface | <1 |

| Monocalcium Phosphate | 0.5 | 6 | Removal of Crystal Water on the Surface | <1 |

| Silicon Dioxide | 0.5 | 7 | 80 | <5 |

| Pseudo-Boehmite | 0.4 | 1 | 60 | 0 |

| Light Calcium Carbonate | 0.6 | 8 | 65 | <2 |

| Tungsten Concentrate Powder | 0.4 | 7 | 30 | <1 |

| Bismuth Concentrate Powder | 0.4 | 7 | 30 | <1 |

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.