Vacuum Paddle Dryer (Mechanical Seal)

Key words

Category

Enquiry

Parameter download

Introduction

◆jinling is a professional manufacturer of vacuum paddle dryers. This model is the thrd- generation product designed and upgraded by our company.

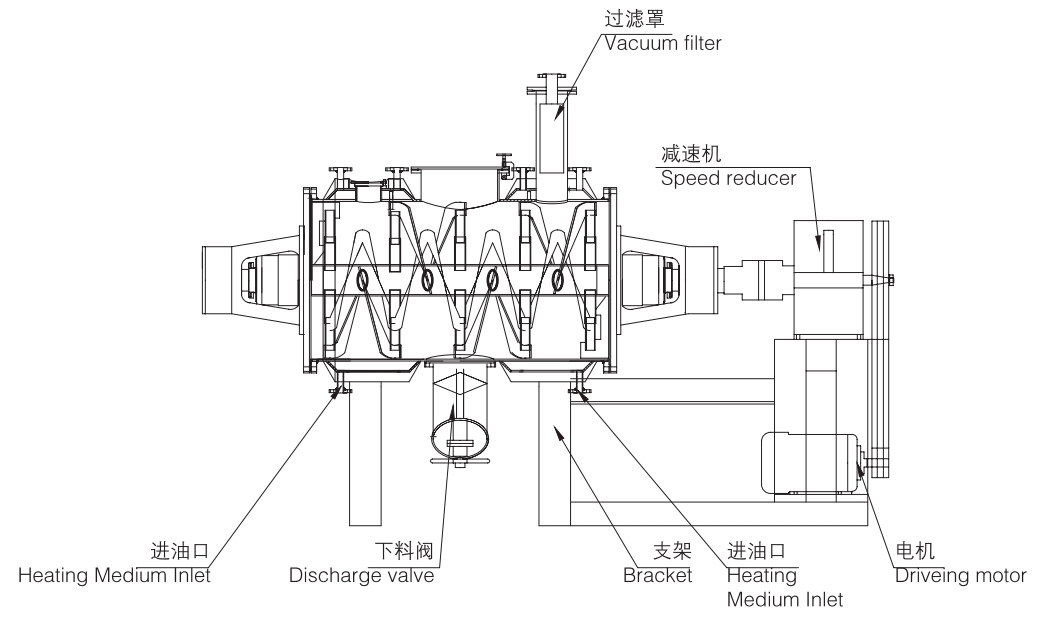

◆Our company made a series of innovative improvements to the system in 2003. mainly focusing on thermal expansion, concentricity, shaft sealing, discharge valve, transmission structure, mixing mechanism, strength of main shaft, shaft heating. bearing structure, internal structure of mechanical seal, etc. Overall, mechanical seals can be used for vacuum drying instead, which has greatly improved the sealing performance and service life. This model is also applicable for large -scale dryingmachines with high vacuum level.

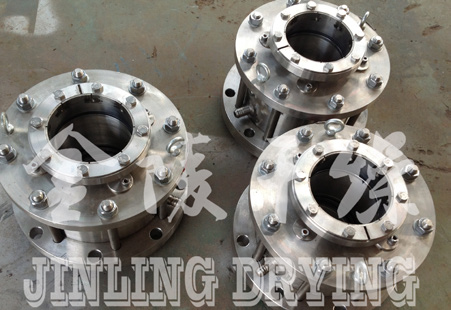

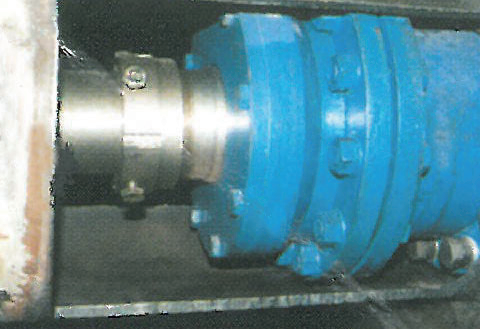

◆The mechanical seal structure is mainly used to maintain a high vacuum level for a long time and efectively prevent impurities from entering the material. Generally, single-end mechanical seals, corrugated mechanical seals and double-end mechanical seals are used. The end-face materials are generally graphite, silicon carbide, and aloy steel.

◆In order to ensure the artightness and the service life of the dryer, a series of innovative designs and processing techniques have been applied, especially for the materials with high resistance towards abrasion and corrosion, such as salts, liquids, solvents, etc. in order to significantly improve the performance of equipment in terms of shaft runout, expansion and extension, stability, and the service life. Our company is currently the top-class manufacturer of vacuum paddle dryers domestically.

◆jinling developed and designed diferent paddle blade structures for diferent drying conditions: spiral belt style, shoveling plate style, disc style, triangular strring paddle style, coulter style, etc. Also, heating method inside the shaft can be designed to increase specifc surface area and improve drying eficiency.

Flow Chart

Our Customers(Partial)

◆Jiangsu Huifeng Agrochemical Co., Ltd Over 100 sets

◆Zhejiang Lvke'an Chemical Co., Ltd 10m318 sets

◆Jiangsu Jianpai Agrochemical Co., Ltd 8 sets

◆Shandong Shuangtao Chemical Co., Ltd 10m34 sets

◆Zhejiang Yingtai Chemical Co., Ltd 3m312 sets

Technical Specifications

| Model | Unit | ZHG -500 | ZHG -1000 | ZHG -1500 | ZHG -2000 | ZHG -3000 | ZHG -4000 | ZHG -5000 | ZHG -6000 | ZHG -7000 | ZHG -10000 | ZHG- 12000 | ZHG -20000 |

| Working Volume | L | 300 | 600 | 900 | 1200 | 1800 | 2400 | 3000 | 3600 | 4200 | 6000 | 7200 | 12000 |

| Size of Inne Barrel | mm | Ø600 x1500 | Ø850 x1800 | Ø1000 x2000 | Ø1200 x2000 | Ø1200 x2700 | Ø1400 x2700 | Ø1500 x3000 | Ø1500 x3500 | Ø1600 x3600 | Ø1700 x4500 | Ø1800 x4800 | Ø2200 x5500 |

| Stirring Speed | rpm | 5-12 | 1 | 0 | 3~10 | ||||||||

| Power | kW | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 22 | 30 | 37 | 45 | 75 |

| Pressure inside Barrel | Mpa | -0.09~0.096 | |||||||||||

Related Equipment

Leave your needs behind

We will contact you within one working day. Please pay attention to your email.